scodanibbio.com

Carlo Scodanibbio Industrial & Business Consultant Lean Management Consultant |

public traininghome profile consulting training events contact |

scodanibbio.com

Carlo Scodanibbio Industrial & Business Consultant Lean Management Consultant |

public traininghome profile consulting training events contact |

"...in a rapidly changing world, featuring vanishing borders and hot, global competition, all industrial and business concerns, including SMEs, must aim at new performance targets in line with 'the best in the class-room' as recipe for success or - at least - survival..."

Nothing will happen in those enterprises that do not know where they stand. No real improvement can take place... Because they stand in soft, loose ground, or even quicksand.... so that any attempt to improve will most probably make them sink even more...

Knowing the present level of performance by measuring it creates a solid launch pad and an associated tension from which subsequent improvement initiatives can get powered and take-off.

An important objective of this course is to enable participating enterprises to learn how to "measure".

But the most important objective of this course is to make participating delegates aware that, today, the only possible and valid "direction" for improvement initiatives is the "lean" direction.

Many enterprises have undergone continuous improvement programs without a direction. Caught by improvement enthusiasm, people have tried to improve just "anything", at 360°, following the motto "today better than yesterday, tomorrow better than today".

This is what I call the "black & white TV set mistake", or going for spurious, fictitious improvement that leads nowhere.

To get somewhere, enterprises must go "lean".

Going "lean", or targeting at real "excellence", is a total "thinking revolution".

LEAN ISN'T AN OPTION ANY MORE - IT'S A NECESSITY!!!!!!

WALK AWAY HAVING POWERFUL GRASP OF WORKING SKILLS TO:

Venue: Malta Enterprise - San Gwann - Malta

Date: 4-6-8 October 2010

Timing: Registration will be at 08:00 with the workshop beginning at 08:30 and concluding at 17:00.

There will be a 15' break for refreshments in the morning and the afternoon (at approx. 10:15 and 15:15 respectively) and lunch will be served at 12:30.

All timings are approximate due to the interactive and intensive nature of the workshop.

This highly interactive course is designed to provide participants with practical and 'hands-on' insights on Lean Kaizen practices, along with effective tools & techniques to achieve desired outcomes through practical case studies and live simulations. Derived from Dr. Carlo's extensive experience on Lean processes, this course will be conducted with a highly engaging and result-oriented approach that gives you immediate and substantial results.

Business Strategists - Chief Executive Officers - Managing Directors - General Managers - Continuous Improvement Leaders and Champions - High and mid-level Managers (Operations, Production, Quality, R&D, Engineering, Maintenance, HR, Administration, Commercial…..) from private enterprises (manufacturing and assembly - service establishments and commercial enterprises - project/contract-driven and construction) of all sizes and public/governmental organisations.

The very small enterprise (up to 20 employees) will particularly benefit from participating in this course.

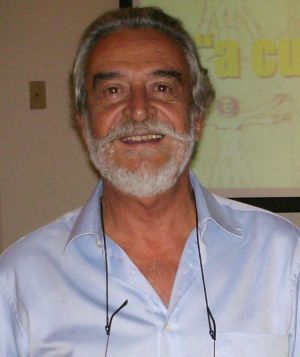

Carlo Scodanibbio, born in Macerata (Italy) in 1944, holds an Italian doctor degree in Electrical Engineering (Politecnico di Milano - 1970).

Carlo Scodanibbio, born in Macerata (Italy) in 1944, holds an Italian doctor degree in Electrical Engineering (Politecnico di Milano - 1970).

He has over 40 years of experience in Plant Engineering, Project Engineering and Project Management, as well as Industrial Engineering and Operations Management.

Free-lance Consultant since 1979, he has worked in a wide spectrum of companies and industries in many countries (Southern Africa - Italy - Cape Verde - Romania - Malta - Cyprus - Lebanon - Mauritius - Malaysia - Kenya - India - Saudi Arabia), and operates as an Independent Professional Consultant and Human Resources Trainer to industry.

His area of intervention is: World Class Performance for Small and Medium Enterprises in the Project, Manufacturing, and Service sectors.

His favourite area of action is: the "lean" area.

He has co-operated, inter-alia, with the Cyprus Chamber of Commerce, the Cyprus Productivity Centre, the Malta Federation of Industry, the Malta Chamber of Commerce and Industry, the Mauritius Employers' Federation, the Romanian Paper Industry Association, the United Nations Industrial Development Organisation and the University of Cape Town.

His workshops and seminars, conducted in English, Italian and French, have been attended by well over 14.000 Entrepreneurs, Managers, Supervisors and Workers. They feature a very high level of interaction, and are rich in simulations, exercising and real case studies. The approach is invariably "hands-on" and addressed to immediate, practical application.

Joseph Micallef graduated in electrical engineering from the University of Malta in May 1992. He has been involved in the manufacturing industry since 1990. Initially starting his career within the medical devices and plastics processing manufacturing sector, he later moved on within the electronics manufacturing sector.

Joseph Micallef graduated in electrical engineering from the University of Malta in May 1992. He has been involved in the manufacturing industry since 1990. Initially starting his career within the medical devices and plastics processing manufacturing sector, he later moved on within the electronics manufacturing sector.

Throughout his career, Joseph has had experiences in a variety of industrial and automation processes, research and development projects, various manufacturing processes and occupied senior technical and management roles in research and development, process control, quality management, occupational health safety and business process management. For the last c. 14 years, Joseph has been occupying the position of Quality Manager within a very dynamic high tech electronics manufacturing industry sector.

Apart from his broad industrial experiences gained through the last c. 20 years, Joseph has also paralleled his experience within the services sector through his various freelance projects which he has undertaken since the year 2000 when he had ventured into the freelance consultancy and mentoring/training business.

Joseph's career spreads primarily in Malta, but he has been assigned several projects and training opportunities in various countries within Europe (UK, Scotland, Belgium, France, Finland, Italy), the US (Jacksonville, Houston) and the Middle East (Egypt).

Ing. Joseph Micallef is a corporate member of a number of institutions. In particular he is registered Chartered Engineer with the Engineering Council (UK) - C.Eng., corporate member in the Institution of Engineering and Technology (UK) - MIET, European engineer through FEANI - Eur.Ing., and warranted member within the Chamber of Engineers (Malta).

Dear Delegate(s),

This course will be a shocking course for many of you. Because it demystifies all traditional principles of the first industrial revolution on which the majority of enterprises, still today, are built or around which they operate. By presenting in rather great detail the philosophy of the second industrial revolution and the main tools and disciplines readily available to all enterprises to perform in an "excellent" status, this course is a door-opener to lean practices for whoever is: ready to listen to message - prepared to abandon obsolete principles, formulas and approaches - willing to get to "lean" status.

This course will prove that competitiveness today can no longer be achieved by merely cutting costs or revamping technology: because cutting costs has a floor, while performance improvement through maximisation of value-added and waste elimination has no ceiling -and because technology alone does not generate the levels of output value enterprises and organisations need to tackle the challenges of the new millennium.

By showing that "thinking" is what must change at all levels of an organisation, this course will prove that higher levels of performance can be achieved if you create the right conditions.

I GUARANTEE that you will leave this workshop with the knowledge and tools to improve the value proposition of your organisation!

See you soon in San Gwann!

Dr. Carlo Scodanibbio

An excellent seminar, well presented, realistic, to the point. Excellent for making managers see the companies in a different manner.

[V L - Assistant General Manager - Chr. Avraamides & Co. Ltd - Nicosia - Cyprus]

Course content of very high value. Can see my way forward with this "lean" concept. Presentation conducted very professionally. Excellent course, enjoyed it immensely.

[D F - Production Manager - Plaaskem - Boksburg - South Africa]

An excellent course. It's a cultural change that will have to take place.

[W O - Factory Manager - Ceres Fruit Juices - Ceres - South Africa]

An excellent seminar. I found the presentation dynamic & very open minded. I believe CS richness comes from the very people he comes across to train, apart from his own learnt experience.

[J B - Administrative Manager - Atelcom Ltd - Mauritius]

An excellent course. Will recommend this to any department or small business that wants to start adding more value by using or applying basic and practical methods.

[L P - Lab. Engineer - Circuit Breaker Industries Ltd - Isando - South Africa]

Excellent course, I cannot wait to start to implement what I have learnt in practice!!

[R G - Operations Manager - Namibia Beverages - Windhoek - Namibia]

An excellent course, it was absolutely brilliant

[G K - Production Manager - Distell Ltd. - Bergkelder - South Africa]

An excellent course, very informative and an eye opener. We need this in South Africa.

[H L - Training Specialist Technical Services - Distell Ltd. - Stellenbosch - South Africa]

An excellent course. It has opened my eyes to a lot of weaknesses in my plant. I go away with a lot of things to do!

[P M - Factory Manager - Polymer Concrete Industries - Kitwe - Zambia]

I am impressed with the approach and the presentation of the course in general.

[J K - Manufacturing Manager - Nissan Diesel SA - South Africa]

...it has opened a way in my work where I need to improve, especially on waste reduction…

[H K - Production Manager - Brookside Milk - Nairobi - Kenya]

An excellent seminar. Excellent passing over of information. Excellent style of teaching - crystal clear. Extremely helpful advice.

[V A - General Manager - Pappagallo Clothing Industry - Nicosia - Cyprus]

An excellent Seminar: both enlightening & enjoyable - thank you

[M M - Cyprus Productivity Centre - Nicosia - Cyprus]

An excellent course. It was interesting to see how we accept the day-to-day operation as being acceptable, and once highlighted the areas that can be improved and adjusted to eliminate waste and non-value-adding operations or incidents.

[L V V - Factory Manager - C. H. Warman Pump Group - Alberton - South Africa]

An excellent seminar, very informative for me - and I do believe that a big part of it can be applied in practice - it is not at all a theoretical course. Finally I have to admit that I am very impressed about the way Dr Carlo Scodanibbio present the topics.

[L A - Managing Director - Aldecor Trading Ltd - Larnaca - Cyprus]

An excellent course. Enjoyable presentation, very good review of "lean" principles with excellent practical examples.

[H W - Manufacturing Manager - Sandvik - South Africa]

An excellent seminar. The ideas presented during the seminar and the methods for their application have changed my approach to the whole manufacturing concept.

[P N - Director - S.S. Neocleous & Sons Ltd - Nicosia - Cyprus]

An excellent seminar. I believe that any seminar whichever must be conducted by someone who is capable, has true art of teaching, brilliant, ready to help, smart to the point, assuring, good observer, and with comprehensive knowledge, as Mr. Carlo Scodanibbio. I have enjoyed the course and learnt to my entire satisfaction.

[S E - Personnel Manager - Desbro International Ltd - Mauritius]

An excellent course, one of the best I have attended. Carlo holds your attention well.

[T D - Factory Manager - Sara Lee - South Africa]

An excellent seminar. The message of "World-Class Performance" was given once more with an excellent presentation and accurate information.

[A G - Managing Director - Aias Ltd - Nicosia - Cyprus]

An excellent course. I sincerely enjoyed and gained a lot out of these last days. I thank you sincerely.

[N O - Production Manager - Mecer Computers - South Africa]

The way this course was presented was excellent..... with a lot of interaction..... CS is an excellent instructor, combining his own experience, conveying messages..... thank you very much

[P C - Electricity Authority - Cyprus]

An excellent course. I like its style. It encourages a lot of discussion and there is not a lot of jargon. It deals with the real life challenges we face daily in our jobs.

[C N - Factory Manager - Nestlé SA - South Africa]

An excellent seminar. I started by having doubts about attending this seminar (...no time, you know....). I think it is one of the best decisions I have made during the last year is not to have missed it

[A M - Plant Manager - Pharmaline - Sarraf Group Sal - Beirut - Lebanon]

This was an excellent course to be recommended to all industries in SA, not only to equate productivity to finance but to have a holistic view of the outcomes thereof.

[P S - Manager - Transwerk - South Africa]

An excellent seminar - many many thanks once again, for helping me to "see"...

[A H - Technical Manager - Wonder Foods - Nairobi - Kenya]

more testimonials

FEES and DISCOUNTS STRUCTURE (Prices are per Delegate and excluding VAT):

° Price per 1 Delegate Euro 460,00

° 2 Delegates: less 5% Euro 437,00

° 3-5 Delegates: less 10% Euro 414,00

° 6-9 Delegates: less 15% Euro 391,00

° 10+ Delegates: less 20% Euro 368,00

EARLY BIRD REGISTRATION

Please note: the normal deadline for course registration is strictly by the 24th September 2010.

Early Bird Registration: register and settle workshop Fees by 15th September, 2010 and get an additional 10% discount on the applicable price (as per Fees Structure above)

To download a Printable workshop Brochure (pdf) please right-click here (save object as....).

TERMS OF PAYMENT

Fees include: participation in the 3-day course "Next Generation Lean Manufacturing" to be held on 4-6-8 October 2010 - Refreshments and Lunches - workshop Notes and Documentation - Certificate of Achievement (Certificate of Successful Completion, against satisfactory results in the course's final exam) signed by Dr. Carlo Scodanibbio and Ing. Joseph Micallef.

Upon receipt of a duly completed and signed Registration Form, a Confirmation Letter and Invoice will be sent to you.

Payment of workshop Fees is strictly on presentation and is required within 5 working days from date of Invoice.

CANCELLATION POLICY

All Cancellations of Registrations must be made in writing. Due to contractual obligations, a cancellation charge of 30% of the invoiced amount applies if the cancellation is received 10 days or less before Course starting date.

However, a complete set of documentation will be sent to you.

Substitutions are welcome at any time.

Should the workshop be cancelled by force-majeure or for any other reason, you will receive a full refund of the paid workshop Fees.

TRAINING GRANTS

Training Grants ranging between 60 and 80% are available to eligible enterprises through the Training Aid Framework (TAF) Scheme administered by the ETC.

Deadline for Training Grants Application: 10 September 2010.

Please note: the onus to apply for a Training Grant rests on the participating enterprise. You may contact the Course Leaders for some basic information on how to apply for a Training Grant.

For administrative and technical enquiries please contact directly the workshop Leaders:

Dr. Carlo Scodanibbio

Tel. (+356) 2166 2115 - Mob. (+356) 7996 6056 - e-mail:

Ing. Joseph Micallef

Mob. (+ 356) 9982 2244 - email: