|

navigation

consulting

services

training

services

specials

reading

material

resources

|

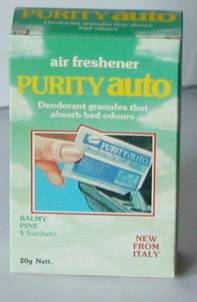

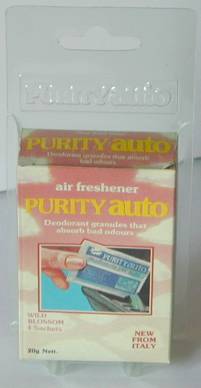

A small (but rather profitable) enterprise based in a Country of the Southern Hemisphere imports from Italy, packages and sells locally an air freshener by the name of Purity Auto.

FACTS AND DATA

Product

Purity Auto granulated deodorant and air freshener in "sachets" marketed as:

-Purity Auto Display Box of 24 packs (of 4 sachets each) - Display Boxes may contain assorted fragrances packs or one fragrance packs

-Purity Auto Blister Pack (of 4 sachets each) in a carton of 24 blisters - cartons may contain assorted fragrances blister packs or one fragrance blister packs

-Purity Auto Sachets in bulk, in carton of 200 sachets - cartons may contain assorted fragrances or one fragrance sachets

-Purity Auto Sachets in bulk, in carton of 50 sachets - cartons may contain assorted fragrances or one fragrance sachets

Each sachet contains 5 grams net of deodorant granules.

There are 6 available fragrances, all imported.

The product is unique, patented world-wide, and has practically no direct competitor. It is very popular, and simply promoted by "word of mouth". The product is also promoted directly at shows and fairs.

Components List

a) Display Box of 24 Packs

24 empty Packs - 1 fragrance or assorted

24 Instruction Leaflets

96 Sachets - 1 fragrance or assorted

1 Display Box

1 Packaging Operator number reference tag (for traceability purposes)

1 Cardboard Box

Sealing Tape

1 Dispatch Label

b) Carton of 24 Blister Packs

24 empty Packs - 1 fragrance or assorted

24 Instruction Leaflets

96 Sachets - 1 fragrance or assorted

24 Vacuum formed Blisters

1 Packaging Operator number reference tag (for traceability purposes)

1 Cardboard Box

Sealing Tape

1 Dispatch Label

c) Carton of 200 Sachets in bulk

200 Sachets - 1 fragrance or assorted

1 Instruction Leaflet

1 Packaging Operator number reference tag (for traceability purposes)

1 Cardboard Box

Sealing Tape

1 Dispatch Label

d) Carton of 50 Sachets in bulk

50 Sachets - 1 fragrance or assorted

1 Instruction Leaflet

1 Packaging Operator number reference tag (for traceability purposes)

1 Cardboard Box

Sealing Tape

1 Dispatch Label

Sales data

Approximately 2.000.000 Sachets of 5 grams are sold in 1 year. Sales are steadily increasing at a

rate of approx. 10% per year.

75% of Sales consist of Display Boxes (68% assorted and 7% one fragrance).

20% of Sales consist of Blister Packs (practically all in assorted fragrances).

5% of Sales consist of Sachets in bulk (4% in cartons of 200 and 1% in cartons of 50) - practically

all in assorted fragrances.

Practically all fragrances are equally popular and equally sold.

Typical Customers are:

Service & Petrol Stations

Supermarkets & Departmental Stores

Car Wash

Motor Car Spares & Accessories Shops

Hardware Shops

Tobacconists

Florists

Chemists

Health Shops

New and 2nd hand Motor Car Dealers

Caravan & Camping Shops

Orders are received daily, by phone or fax. On average, 15 - 25 orders are received every day.

On average, 60 - 100 product units (display boxes, cartons of 24 blister packs.....) are dispatched daily.

The minimum order size accepted is 2 product items. Generally, each individual order does not exceed 10 product items.

Customers order 1 type only of product: i.e., Customers who order Assorted Fragrances Display Boxes only order that type of product - Customers who order Cartons of Sachets in bulk, only order that type of product - and so on....

Distribution & Dispatching

Through "XXXX Fast Delivery Services", Country wide. The delivery company collects from the factory twice a day (generally at 09:00 and 14:00) the goods to be dispatched.

The current motto is: "dispatch today what customers ordered yesterday". This is achieved through large back-up stock of finished product.

Procurement

Granules are imported in bulk, in drums containing 20 Kg net of product. The economic order lot has been found to be approx. 45 drums, arriving ex import on a monthly basis.

Drum size : dia. 35 cm height 50 cm

Empty Sachets are also imported from the overseas supplier together with the granules. Approx. 180.000 sachets are imported every month. Sachets come in pairs, and are pre-printed with fragrance's name.

They are supplied in cartons of 10.000 sachets. Carton's size : 60 x 20 x 10 cm

All the other components are of local manufacture.

Empty Display Boxes are supplied in batches of 4000 every 3 months. They come in a carton

containing 100 flat Display Boxes. Carton's size : 90 x 40 x 18 cm

Empty Packs are supplied in batches of 120.000 every 3 months. They come in cartons containing

1000 flat packs. Carton's size : 40 x 40 x 25 cm Empty Packs are supplied in batches of 120.000 every 3 months. They come in cartons containing

1000 flat packs. Carton's size : 40 x 40 x 25 cm

Empty Cardboard Boxes for protection/dispatch of Display Boxes are supplied in lots of 700 every 2 weeks. They come in bundles of 100 flat cartons. Bundle's size : 70 x 70 x 50 cm

Empty Blisters are supplied in monthly batches of approx. 8500. They come in cartons containing 500 blisters. Empty blisters fit the one inside the other, so they are stackable. Carton's size : 60 x 40 x 20 cm Empty Blisters are supplied in monthly batches of approx. 8500. They come in cartons containing 500 blisters. Empty blisters fit the one inside the other, so they are stackable. Carton's size : 60 x 40 x 20 cm

Empty Cardboard Boxes for 24 Blister Packs are supplied in batches of approx. 200 every 2 - 3 weeks. They come in bundles of 100 flat cartons. Bundle's size : 60 x 60 x 70 cm

Empty Cardboard Boxes for 200 Sachets are supplied in a single lot of 400, approx. once a year. They come in bundles of 100 flat cartons. Bundle's size : 50 x 50 x 70 cm

Empty Cardboard Boxes for 50 Sachets are supplied in a single lot of 400, approx. once a year. They

come in 1 bundle of flat cartons. Bundle's size : 25 x 25 x 50 cm

Instruction Leaflets (folded, except last fold) are supplied in lots of 40.000 approx. every month. They come in cartons containing 10.000 folded leaflets. Carton's size : 40 x 40 x 50 cm Instruction Leaflets (folded, except last fold) are supplied in lots of 40.000 approx. every month. They come in cartons containing 10.000 folded leaflets. Carton's size : 40 x 40 x 50 cm

Processing ancillaries (sealing tape, labels, tags....) are all of local manufacture and readily available.

Processing Operations

Granules are packaged in special sachets (imported) by means of two dosing/filling/sealing machines, manually operated. Granules are packaged in special sachets (imported) by means of two dosing/filling/sealing machines, manually operated.

A drum's content is poured into the machine hopper (sealable). A pair of sachets is positioned in the dosing unit : they are filled with 5 g. of granules each, and then hermetically thermo-sealed.

The cycle time (real) for this operation is 7,2 seconds. In an 8 hrs. shift each machine can produce 8000 sachets.

A drum of granules should be packaged possibly within the day (or latest by next day), to preserve the fragrance effectiveness.

Each machine has a counter (resettable) to know production details.

Sachets are supplied overprinted with fragrance name.

Filled sachets are thrown higgledy-piggledy into cartons of large size. Cartons may contain 1000 sachets, approximately, but real content is never known. Cartons of full sachets (each fragrance) are stored before further processing, and constitute buffer stock (WIP).

Sachets are then packaged either into

a) Packs, or

b) directly into Cartons containing 50 or 200 sachets

a) Packs packaging process consists of inserting 4 sachets (of one fragrance) and one Instruction Leaflet into a Pack. a) Packs packaging process consists of inserting 4 sachets (of one fragrance) and one Instruction Leaflet into a Pack.

The associated Cycle Time [pick-up empty, flat Pack - open it up - close bottom - pick-up 4 Sachets - pick up Instruction Leaflet - fold (last fold) Instruction Leaflet - insert 4 Sachets and Instruction Leaflet into Pack - close its top - throw full Pack in a large carton - pick-up empty Pack - etc.] is approximately 5 seconds.

Packs are fragrance coded, bar coded, and of different colours according to fragrance. Packs are fragrance coded, bar coded, and of different colours according to fragrance.

Full Packs are temporarily stored in bulk (higgledy-piggledy) in large cartons (one fragrance per carton), before being further processed (WIP).

Packs are then, either:

a.1) inserted into a Display Box, containing 24 Packs of one fragrance or assorted fragrances. a.1) inserted into a Display Box, containing 24 Packs of one fragrance or assorted fragrances.

Each packaging labourer has a reference number, and a tag bearing her number is inserted into the Display Box for traceability purposes.

The associated Cycle Time [pick-up empty, flat Display Box - open it up - position it on the workbench - pick-up full Packs from large carton - position them into Display Box - insert reference Tag - close Display Box - position full Display Box in a pile - pick-up empty Display Box - etc.] is approx. 25 seconds in the case of one fragrance Display Boxes and 35 seconds in the case of assorted fragrances Display Boxes.

Generally, the assortment consists of an equal number of Packs of each fragrance (4 Packs per fragrance).

Full Display Boxes are stored on shelves with distinct areas for one fragrance Display Boxes and each one fragrance Display Boxes.

There is always a consistent buffer stock of Display Boxes.

At dispatch time, the Display Boxes are picked up from the storage shelves, brought to a workbench, and then inserted into a Cardboard Box (to be protected during delivery), which is sealed with sealing tape. A self-adhesive label is then stuck onto the Cardboard Box. At dispatch time, the Display Boxes are picked up from the storage shelves, brought to a workbench, and then inserted into a Cardboard Box (to be protected during delivery), which is sealed with sealing tape. A self-adhesive label is then stuck onto the Cardboard Box.

The label specifies, besides all general manufacturer's details, the content of the Cardboard Box, and the full delivery address.

All dispatch labels are manually prepared in the Office by a Clerk, and given to the packaging labourers according to orders received.

The cartonising Cycle Time [pick-up empty, flat Cardboard Box from bundle - open it up - close bottom - seal bottom with self adhesive sealing tape - turn it around - pick-up full Display Box - insert it into Cardboard Box - close top - seal it with sealing tape - pick-up dispatch label - stick it onto Cardboard Box - position completed Cardboard Box on side of workbench - pick-up empty..... - etc.] is approx. 20 seconds.

Display Boxes ready for Dispatch are then brought into Dispatch Area, matched with Delivery Note, and positioned in small dispatch piles together with Delivery Note.

a.2) inserted into vacuum formed Blisters, and temporarily stored in bulk (higgledy-piggledy) in large cartons containing one fragrance. a.2) inserted into vacuum formed Blisters, and temporarily stored in bulk (higgledy-piggledy) in large cartons containing one fragrance.

The associated Cycle Time [pick-up empty Blister - pick-up full Pack - insert Pack into Blister - throw full Blister into large carton - pick-up empty..... - etc.] is approximately 2,5 seconds.

Cartons are stored as buffer stock.

In a subsequent operation, Cartons of 24 Blister Packs (one fragrance or assorted) are prepared. The associated Cycle Time [pick-up empty, flat Cardboard Box from bundle - open it up - close bottom - seal bottom with self adhesive sealing tape - turn it around - pick-up full Blister Pack - position it in Cardboard Box - pick-up full Blister Pack - position it in Cardboard Box - etc. for the 24 Blisters - pick-up reference Tag - put it in Cardboard Box - close top of Cardboard Box - seal it with sealing tape - position full Cardboard Box on side of Workbench - pick-up empty.... - etc.] is approx. 30 seconds in the case of one fragrance Carton and 40" in the case of assorted fragrances.

Blister Packs are so designed as to interlock easily in the Cardboard Box with a rather tight fit.

Full Cartons of Blister Packs are stored onto shelves (buffer stock) in distinct areas according to fragrance or assorted.

At dispatch time, they are brought to a workbench and processed further by sticking onto them the self-adhesive Dispatch Label. Associated Cycle Time is negligible (around 1 second).

b.1) Packaging 50 Sachets into a Carton of 50 consists of: preparing Cardboard Box - counting 50 sachets (one fragrance or assorted) and inserting them into the Cardboard Box with instruction leaflet and Packaging Labourer tag - closing cardboard box with sealing tape - and storing it (buffer stock) on shelves. b.1) Packaging 50 Sachets into a Carton of 50 consists of: preparing Cardboard Box - counting 50 sachets (one fragrance or assorted) and inserting them into the Cardboard Box with instruction leaflet and Packaging Labourer tag - closing cardboard box with sealing tape - and storing it (buffer stock) on shelves.

The associated cycle time is approx. 45" for one fragrance carton and 60" for assorted fragrances.

b.2) Packaging 200 Sachets into a Carton of 200 consists of: preparing Cardboard Box - counting 200 sachets (one fragrance or assorted) and inserting them into the Cardboard Box with instruction leaflet and Packaging Labourer tag - closing cardboard box with sealing tape - and storing it (buffer stock) on shelves.

The associated cycle time is approx. 2' 10" for one fragrance carton and 2' 40" for assorted fragrances.

At dispatch time, they are brought to a workbench and processed further by sticking onto them the self-adhesive Dispatch Label. Associated Cycle Time is negligible (around 1 second).

The above processing cycle times do not account at all for all the preparation time (bring stock from shelves onto workbenches) and clearing/clean-up time (carry stock just prepared to storage or to dispatch area, as the case may be). These times are unknown, but of very high incidence in man-hours.

Labour

Presently there are 2 labourers employed full time, and casual labour employed on a daily basis, amounting often to another 4 and even 5 units.

All the labourers are women, glad to work overtime (which occurs very often), and rather well trained, due to the simple nature of the work to be executed.

The feeling is that a large amount of man-hours is wasted in preparation work, conveyance, clearing and cleaning-up, and idling, waiting, talking.......

Two casual labourers are almost full time at the filling machines, and this is excessive (one should be able to do the job, possibly with some overtime).

Two casual labourers are busy packaging practically every day (and sometimes they become 3).

One permanently employed woman helps practically full-time with packaging and ancillary operations, and co-ordinates the casual labourers. She also helps the other permanently employed labourer, who does all the office work (taking orders, preparing delivery notes, preparing labels.....) and, in some spare time, also assists with co-ordination and manual work.

All the labourers are fully interchangeable with regard to the manual operations.

The owner/manager of the small enterprise is busy practically full-time with : administration work, production planning/scheduling, giving production instructions to labourers and co-ordinators, attending to procurement, assessing stocks, doing public relations, etc.

In spite of the considerable profits his business is making (due to high selling prices in a monopoly situation...), his feeling is that there is a lot of waste and lack of organisation all around.

Recently he has decided to sell his business, and buyers are cueing.

Factory Layout

You may see the present layout by clicking here.

In spite of the about 300 sq.m. of space available for storage/production, the working area is always in a terrible mess, with cartons of sub-assemblies (packs, blisters, display boxes, full sachets, etc.) all over the show, and labourers moving all the time to fetch stock or to carry finished product and sub-assemblies.

THE PROBLEM

It is felt that the present layout, present processing method, present storage method and logistics, and present costs (especially manpower) are not optimal at all.

Stock is excessive, with special regard to finished product (equivalent to approx. one month's sales).

On the other hand stock assures responsiveness to customers' orders, and such responsiveness must be kept.

But catering for special orders (special assortments, or orders for goods not kept in stock in sufficient quantities) always create a major disruption in the productive process.

Quality is fine all along the productive process, however, various hiccups occur during final packaging/dispatch: products are mixed up in the cartons (for instance assorted instead of one fragrance Display Boxes, or Blister Packs cartons.....).

Sometimes deliveries have to be double checked and re-opened just before dispatch, as some confusion arises.

There are also some returns for the same reason.

Test your skills

Should you be the buyer of this business and, as such, become the new owner/general manager, how would you re-engineer the present set-up?

The target is to minimise overall costs and P-time, maximising responsiveness to customers ordinary and special needs, and eliminating all (few) non-quality aspects.

A possible solution

If you are impatient, you may see what the actually adopted solution was by clicking here.

|