scodanibbio.com

Carlo Scodanibbio Industrial & Business Consultant Lean Management Consultant |

public traininghome profile consulting training events contact |

scodanibbio.com

Carlo Scodanibbio Industrial & Business Consultant Lean Management Consultant |

public traininghome profile consulting training events contact |

https://www.scodanibbio.com/malta2011/

Announcing: https://www.scodanibbio.com/malta2012/

| QUICK LINKS | ||

| Foreword | Training Modules: program and details of events | About Your Facilitators |

| From the Desktop of Dr. Carlo and Ing. Joseph | Quotes from Previous Delegates | Enquiries - Contact Us |

MALTA 2011 - LEAN BUSINESS EXCELLENCE is a revolutionary, comprehensive training program on lean principles developed by Carlo Scodanibbio and Joseph Micallef.

THE PICTURE - THE NEED

In the entire industrial/business world there are considerable attempts to embrace lean practices as a strategy for survival and excellence.

What happens in Malta in this regard? (pleaseread more notes in this respect further below).

Not much - and definitely not enough. In spite of many private organisations having tried over the years to adopt the Lean philosophy (or part of it), the overall industrial/business environment has not yet made significant steps to change culture and mentality.

Over the years, we have trained many hundreds (if not thousands) of delegates from the various business sectors (Manufacturing, Project/Construction, Service) as well as from the public sector. What are our conclusions?

Quite astonishing, but well understandable:

The picture described above is not brilliant.

A very similar picture also exists in neighbouring, "Mediterranean" Countries (Southern Europe, Northern Africa, Middle East......).

The most critical point, quite certainly, is the lack of cultural change that must necessarily be associated with any lean attempt.

OUR OFFER

From the above, comes the need for a solid training program addressed to:

Since we strongly believe in Lean as a philosophy that can change individuals, groups, teams, organisations, businesses, and an entire Country for the better, we present here below a number of Lean Training Modules all falling under a program we have called LEAN BUSINESS EXCELLENCE Malta 2011.

The program includes modules industry/sector-specific and cross-sectorial. Several modules are well suited also to the Public Sector.

The program caters for personnel at all levels: from top-management to frontline personnel.

The first module is specifically engineered for top managers/directors of private and public organisations: this is what we consider the "big-bang" of our 2011 program, because without continual top management drive and support any lean initiative may actually fail.

For each of the training modules below, you will find:

- a broad description of the contents

- the audience to which it is addressed

- duration, presentation date/s, price

- links: to the detailed Brochure of each event; to its Timetable; as well as to an "Online" and to a printable Registration Form

- a simple form for Expression of Interest in any of the listed events - you may also specify the potential number of attending delegates

We trust you will appreciate the enormous efforts behind this initiative and support it in full.

Carlo Scodanibbio and Joseph Micallef

NB: although this program is dedicated primarily to the Maltese industry, delegates from neighbouring Countries (such as in Southern Europe, Northern/Central Africa, Middle East, etc.) will definitely benefit from attending any of the program's modules.

| QUICK LINKS | ||

| Foreword | Training Modules: program and details of events | About Your Facilitators |

| From the Desktop of Dr. Carlo and Ing. Joseph | Quotes from Previous Delegates | Enquiries - Contact Us |

| QUICK LINKS | ||

| Foreword | Training Modules: program and details of events | About Your Facilitators |

| From the Desktop of Dr. Carlo and Ing. Joseph | Quotes from Previous Delegates | Enquiries - Contact Us |

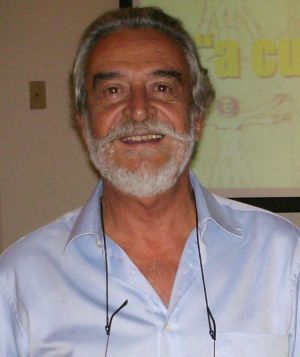

Carlo Scodanibbio, born in Macerata (Italy) in 1944, holds an Italian doctor degree in Electrical Engineering (Politecnico di Milano - 1970).

Carlo Scodanibbio, born in Macerata (Italy) in 1944, holds an Italian doctor degree in Electrical Engineering (Politecnico di Milano - 1970).

He has over 40 years of experience in Plant Engineering, Project Engineering and Project Management, as well as Industrial Engineering and Operations Management.

Free-lance Consultant since 1979, he has worked in a wide spectrum of companies and industries in many countries (Southern Africa - Italy - Cape Verde - Romania - Malta - Cyprus - Lebanon - Mauritius - Malaysia - Kenya - India - Saudi Arabia), and operates as an Independent Professional Consultant and Human Resources Trainer to industry.

His area of intervention is: World Class Performance for Small and Medium Enterprises in the Project, Manufacturing, and Service sectors.

His favourite area of action is: the "lean" area.

He has co-operated, inter-alia, with the Cyprus Chamber of Commerce, the Cyprus Productivity Centre, the Malta Federation of Industry, the Malta Chamber of Commerce and Industry, the Mauritius Employers' Federation, the Romanian Paper Industry Association, the United Nations Industrial Development Organisation and the University of Cape Town.

His workshops and seminars, conducted in English, Italian and French, have been attended by well over 15.000 Entrepreneurs, Managers, Supervisors and Workers. They feature a very high level of interaction, and are rich in simulations, exercising and real case studies. The approach is invariably "hands-on" and addressed to immediate, practical application.

Joseph Micallef graduated in electrical engineering from the University of Malta in May 1992. He has been involved in the manufacturing industry since 1990. Initially starting his career within the medical devices and plastics processing manufacturing sector, he later moved on within the electronics manufacturing sector.

Joseph Micallef graduated in electrical engineering from the University of Malta in May 1992. He has been involved in the manufacturing industry since 1990. Initially starting his career within the medical devices and plastics processing manufacturing sector, he later moved on within the electronics manufacturing sector.

Throughout his career, Joseph has had experiences in a variety of industrial and automation processes, research and development projects, various manufacturing processes and occupied senior technical and management roles in research and development, process control, quality management, occupational health safety and business process management. For over these last c. 14 years, Joseph has been occupying the position of Quality Manager within a very dynamic high tech electronics manufacturing industry sector.

Apart from his broad industrial experiences gained through the last c. 20 years, Joseph has also paralleled his experience within the services sector through his various freelance projects which he has undertaken since the year 2000 when he had ventured into the freelance consultancy and mentoring/training business.

Joseph's career spreads primarily in Malta, but he has been assigned several projects and training opportunities in various countries within Europe (UK, Scotland, Belgium, France, Finland, Italy), the US (Jacksonville, Houston) and the Middle East (Egypt).

Ing. Joseph Micallef is a corporate member of a number of institutions. In particular he is registered Chartered Engineer with the Engineering Council (UK) - C.Eng., corporate member in the Institution of Engineering and Technology (UK) - MIET, European engineer through FEANI - Eur.Ing., and warranted member within the Chamber of Engineers (Malta).

| QUICK LINKS | ||

| Foreword | Training Modules: program and details of events | About Your Facilitators |

| From the Desktop of Dr. Carlo and Ing. Joseph | Quotes from Previous Delegates | Enquiries - Contact Us |

LEAN MANAGEMENT: STILL UNKNOWN IN MALTA?

What does "lean" mean?

It means maximising the value of a product or service provided to a customer while simultaneously minimising any form of waste present in the process that produces such product or service.

Lean Management is a philosophy and an operational discipline aiming at structuring an organisation (public or private) in a "lean" fashion.

The main targets?

1) Maximisation of value to the customer

2) Drastic elimination of waste in all processes (core and support) that generate value for customers

3) Elimination or drastic re-dimensioning of all those processes (and functions) that do not contribute to generate value to the customers

4) Minimisation of all times required to provide value to the customers

5) Zero defects, errors and non-conformities

While many organisations in the most industrialised countries worldwide are striving (or - at least - attempting) to undergo the lean road, what is happening in Malta in this regard? Little, not much - or, not enough - to the writers' opinion.

Lean principles were introduced in Malta over 20 years ago.

Carlo Scodanibbio contributed much in this regard, conducting over the years a number of lean training programs, addressed mostly to the manufacturing and project/construction sectors.

More advanced lean training programs were offered also in the past three years - recently in a joint effort with Joseph Micallef.

What are our conclusions? Quite astonishing. Here are some comments expressed (regularly and repeatedly) by participating delegates:

"....we thought our enterprise was lean (after all, "lean" is not something out of this world), but it is not: now we can see how much waste is still lying around and how lacking is our value offer to our customers..."

"....we heard lean concepts from you many years ago - we understood them - we thought we had done well our homework... - to discover today we have done almost nothing…. - why?"

"....we love these lean principles, but we are not the right delegates in this course - it's our top management that should be sitting here today to listen to these messages...."

"....more than so much we cannot do in our operational area - it's the entire organisation, top-driven, that must become leaner...."

Yes, we thought we were "lean".

Lean is not a mission impossible: lean is basic common sense in business. Unfortunately, it gets easily mis-interpreted. If one asks top managers of private organisations if they think they are lean, most, if not all, will answer is "yes, of course we are lean: we dedicate utmost care to our customers and we are organised in an extremely efficient way. It's even spelt out in our company mission statement - so we are lean.". Is it true?

Generally, it is not. Let's analyse:

MANUFACTURING INDUSTRY

Many manufacturing organisations operating in Malta consider themselves world-class. Many have adopted some lean methods here and there, have introduced some kanban type of pull production, have potentiated their quality assurance system, and have even gone into sophisticated Six-Sigma and other practices. Conclusion? The amount of wasted manpower is still extremely high - plant and machinery breakdowns and malfunctions are still at unacceptable levels - set-up times are still too long - quality defectiveness, non conformities and rejects are still extremely far from the zero-defect lean target - lead times and throughput times are still longer than acceptable to or desired by customers - and management-related waste (in bureaucracy, meetings, paperwork, mis-planning and the like) is still that typical of any "traditional" enterprise.

PROJECT/CONSTRUCTION INDUSTRY

Things are not much better here.

This industry is in some ways not completely shifted from craft to mass production - much less to lean production. On the other hand, the industry has followed the mass production model in its extensive division of labour and hierarchy-based management - Smith & Taylor style. The consequences?

1) Cost Overruns

2) Delays on Schedules

3) Waste

Does one hear often of a project completed in time, within budget and with total client's satisfaction? No, only very seldom. How many examples of considerable and even major architectural mistakes and mishaps can one discover in the Maltese construction industry? Endless. How much wasted manpower is there in the project/construction industry? Just spend some time observing workmen in any construction site, in a random day, at any random time: you will easily come (statistically) to the conclusion that +- 65% of manpower is wasted. Yes, sixty five percent of totally wasted manpower - wasted in idling, searching, moving, talking, double and triple handling, preparing, organising, giving directions, making mistakes, reworking mistakes, and anyhow not adding value to the object of the project. Not to mention pathetic and well known issues related to Public Construction Works and overall Environmental Planning....

SERVICE INDUSTRY

Unfortunately, even worse. The paradox is: it's easier to find good levels of customer service in certain third-world Countries than in Malta. It would appear that good customer care in Malta is something associated only with individual performance of exceptional (and very difficult to find) frontline personnel, rather than being a systematic and strategic approach. Bad service provided by Insurance Companies, Health Institutions, Hospitality Establishments and many other types of Service Providers in Malta is so common that customers have got used to it and don't even notice it anymore: it's simply "normal" and well accepted. Tragic.

Lack of customer care and bad service come in multiple forms (the list could be endless): delays of any nature and duration - mistakes of any sort - arrogance: "we are right you are wrong" (Edward DeBono docet), so diffused in many service establishments, from telephony providers, to retailers and dry-cleaners - referrals of any form of complaint to higher management because, obviously, frontline personnel cannot deal with astronomical issues like a complaint - missed promises to customers ("...I will definitely give you an answer by tomorrow....") - and last but not least the typical "who are you?" when, in English, you call a company and ask for a certain person: in 2010 that "who are you" has not yet been replaced by the much more elegant "...may I ask who is calling?".

Another non-lean phenomenon, not confined to Malta though, draws its origin by the myth of mass production, heritage of the glorious years 70's - 90's of last century. While any normal, typical customer would prefer to be considered and treated on a one-to-one basis, the principle of mass production labels him/her with a "number": you refer a fault to a public service provider and you become a "reference number" - you check-in in a hotel, and immediately you become a "room number" - you board a plane and you become a "seat number" - you have a question on your bank statement, and you are referred to a "call centre" (the new millennium symbol of "efficiency"), most probably requiring from you not only your name, but also a secret customer code and maybe a "call centre PIN number". Obviously, for security reasons.....

Gloomy picture? Let's rather call it realistic, when observed from a Lean Management angle of view.

What is the problem? Organisations (or most of them) seem not to be able to cope with the complexity associated with the changing environment. The more pressure is put on them and the more corrective measures they try to adopt, the worse the results and the more the failures! It's the final coma of the first industrial revolution system, culture and mentality. The only way out of this vicious circle is a revolution in the opposite direction. That's where Lean Thinking comes to the rescue.

The Second Industrial Revolution has started silently over two decades ago. But Malta seems so much attached to the principles, the strategies and the philosophy of the First one, invented by Adam Smith and Frederick Taylor long, long time ago: this is a considerable problem, because the First Industrial Revolution principles are rather "dated", to say the least.

Many delegates attending our courses state that in a "Mediterranean" Country with a "Mediterranean" culture this state of affairs is just normal.

We definitely disagree with this statement. There is nothing wrong with a colourful and character-full Mediterranean culture, mentality and behaviour. To the contrary, it opens wide the doors to lean practices, so much in need for solid, creative thinking (the heart of Lean Thinking and Lean Management).

The only problem is to find a way to marry a "Mediterranean" style with Lean practices; which, however, is not impossible at all.

What is required to the purpose? Techniques (disciplines) and cultural change.

Obviously, disciplines are disciplines, and tools are tools. They can be learnt, they can be obtained, they can be purchased. Culture cannot. Modern, industrial lean culture can only be "fabricated" in-house, within the organisation, by those concerned - starting from top management.

This is the hardest and trickiest part of the transition to "lean": changing culture. Unfortunately, the Smith & Taylor heritage is very heavy. It has taken generations to digest and implement the principles of the first industrial revolution. It will take years or decades to digest those of the second one. Our industrial DNA is heavily polluted by traditional principles. We are still in love with the mass and batch production mentality, with traditional planning, supervision and control. With order and efficiency. With roles, authorities and job descriptions. With rules and procedures. Even hairdressers, retailers, and housewives (yes, housewives!) have fallen in love with mass production principles. The resistance to "lean" is and remains heavy.

We'll need to "slaughter", to change skin, like snakes do. We'll need to transform managers into coaches. We'll need to "fabricate" a new breed of people, people driven by value principles and not by "job" principles. People dedicated to re-conceive, improve and perfect the processes they handle, which they can understand, and for which they must become responsible. People who enjoy working and producing value, and draw satisfaction from it. New millennium craftsman in their workshops. New millennium traders in their shop. In strict contact with their customers. People to whom pride and professional and work dignity, usurped by over a century of labour division and top-control practices, will finally be given back. People who can think: lean (that's why the name: Lean Thinking).

It will take time. With everybody's commitment, much less.

Dr. Carlo Scodanibbio and Ing. Joseph Micallef

| QUICK LINKS | ||

| Foreword | Training Modules: program and details of events | About Your Facilitators |

| From the Desktop of Dr. Carlo and Ing. Joseph | Quotes from Previous Delegates | Enquiries - Contact Us |

An excellent seminar, well presented, realistic, to the point. Excellent for making managers see the companies in a different manner.

[V L - Assistant General Manager - Chr. Avraamides & Co. Ltd - Nicosia - Cyprus]

Excellent course, excellent presentation material & delivery.

[Randolph Alexander Wong Chi Siang - Head of Operation - Power Root (M) - Malaysia]

Course content of very high value. Can see my way forward with this "lean" concept. Presentation conducted very professionally. Excellent course, enjoyed it immensely.

[D F - Production Manager - Plaaskem - Boksburg - South Africa]

An excellent course. It's a cultural change that will have to take place.

[W O - Factory Manager - Ceres Fruit Juices - Ceres - South Africa]

An excellent seminar. I found the presentation dynamic & very open minded. I believe CS richness comes from the very people he comes across to train, apart from his own learnt experience.

[J B - Administrative Manager - Atelcom Ltd - Mauritius]

An excellent course. Will recommend this to any department or small business that wants to start adding more value by using or applying basic and practical methods.

[L P - Lab. Engineer - Circuit Breaker Industries Ltd - Isando - South Africa]

Excellent course, I cannot wait to start to implement what I have learnt in practice!!

[R G - Operations Manager - Namibia Beverages - Windhoek - Namibia]

Excellent course, great explanation

[Noor Atiqah Sharani - Executive, Engineering & Facilities - Padiberas Nasional Berhad - Malaysia]

An excellent course, it was absolutely brilliant

[G K - Production Manager - Distell Ltd. - Bergkelder - South Africa]

An excellent course, very informative and an eye opener. We need this in South Africa.

[H L - Training Specialist Technical Services - Distell Ltd. - Stellenbosch - South Africa]

An excellent course. It has opened my eyes to a lot of weaknesses in my plant. I go away with a lot of things to do!

[P M - Factory Manager - Polymer Concrete Industries - Kitwe - Zambia]

I am impressed with the approach and the presentation of the course in general.

[J K - Manufacturing Manager - Nissan Diesel SA - South Africa]

...it has opened a way in my work where I need to improve, especially on waste reduction…

[H K - Production Manager - Brookside Milk - Nairobi - Kenya]

An excellent seminar. Excellent passing over of information. Excellent style of teaching - crystal clear. Extremely helpful advice.

[V A - General Manager - Pappagallo Clothing Industry - Nicosia - Cyprus]

An excellent Seminar: both enlightening & enjoyable - thank you

[M M - Cyprus Productivity Centre - Nicosia - Cyprus]

An excellent course. It was interesting to see how we accept the day-to-day operation as being acceptable, and once highlighted the areas that can be improved and adjusted to eliminate waste and non-value-adding operations or incidents.

[L V V - Factory Manager - C. H. Warman Pump Group - Alberton - South Africa]

An excellent seminar, very informative for me - and I do believe that a big part of it can be applied in practice - it is not at all a theoretical course. Finally I have to admit that I am very impressed about the way Dr Carlo Scodanibbio present the topics.

[L A - Managing Director - Aldecor Trading Ltd - Larnaca - Cyprus]

An excellent course. Enjoyable presentation, very good review of "lean" principles with excellent practical examples.

[H W - Manufacturing Manager - Sandvik - South Africa]

An excellent seminar. The ideas presented during the seminar and the methods for their application have changed my approach to the whole manufacturing concept.

[P N - Director - S.S. Neocleous & Sons Ltd - Nicosia - Cyprus]

An excellent course. The trainer is well experienced and very inciting and energetic

[Muhamed Amin Firdaus Bin Abu Bakar - Engineer - Padiberas Nasional Berhad - Malaysia]

An excellent course. It gives me new and valuable inputs. Definitely it offers great value for money. What I like most it's something that one can easily relate to.

[Hakimi Mohamad - General Manager - Cement Industries of Malaysia Berhad - Malaysia]

An excellent seminar. I believe that any seminar whichever must be conducted by someone who is capable, has true art of teaching, brilliant, ready to help, smart to the point, assuring, good observer, and with comprehensive knowledge, as Mr. Carlo Scodanibbio. I have enjoyed the course and learnt to my entire satisfaction.

[S E - Personnel Manager - Desbro International Ltd - Mauritius]

An excellent course, one of the best I have attended. Carlo holds your attention well.

[T D - Factory Manager - Sara Lee - South Africa]

An excellent seminar. The message of "World-Class Performance" was given once more with an excellent presentation and accurate information.

[A G - Managing Director - Aias Ltd - Nicosia - Cyprus]

An excellent course. I sincerely enjoyed and gained a lot out of these last days. I thank you sincerely.

[N O - Production Manager - Mecer Computers - South Africa]

The way this course was presented was excellent..... with a lot of interaction..... CS is an excellent instructor, combining his own experience, conveying messages..... thank you very much

[P C - Electricity Authority - Cyprus]

An excellent course. I have gained a lot of knowledge and good ideas.

[Tang Keng Choo - HOD, Technical - Sime Kansai Paints - Malaysia]

An excellent course, good info, I bet I could follow next program

[Mohamed Faroque B. Mohamed Fatillah - Senior Manager, HR - Padiberas Nasional Berhad - Malaysia]

An excellent course. I like its style. It encourages a lot of discussion and there is not a lot of jargon. It deals with the real life challenges we face daily in our jobs.

[C N - Factory Manager - Nestlé SA - South Africa]

An excellent seminar. I started by having doubts about attending this seminar (...no time, you know....). I think it is one of the best decisions I have made during the last year is not to have missed it

[A M - Plant Manager - Pharmaline - Sarraf Group Sal - Beirut - Lebanon]

This was an excellent course to be recommended to all industries in SA, not only to equate productivity to finance but to have a holistic view of the outcomes thereof.

[P S - Manager - Transwerk - South Africa]

An excellent seminar - many many thanks once again, for helping me to "see"...

[A H - Technical Manager - Wonder Foods - Nairobi - Kenya]

En excellent course. Dr Carlo is a very knowledgeable person and his presentation techniques are excellent.

[Mohamad Kamal Hanafiah Bin Abdul Karim - Vice-President, Manager - Bank Simpanan Nasional - Malaysia]

Excellent course and excellent topics and issues. Dr Carlo has shown ways excellent organisations practice lean management.

[Azmi Bin Ali - Manager - Padiberas Nasional Berhad - Malaysia]

An excellent course, I never found myself bored throughout it. I did not want the course to end. The way it was presented was confident and knowledgeable. Presentation: interesting, enlighting and entertaining. I had some night I didn't sleep well - however I know that I will sleep well in future!

[Sean Bell - Factory Manager - J. Ryan Printers - Cape Town - South Africa]

An excellent course, I really enjoyed the movies and case studies

[Michelle Frans - Engineering Manager - SABN - South Africa]

An excellent course, very impressive presentation content and skills - good use of visuals.

[Sean Mandy - National Operations Manager - Nampak Recycling - South Africa]

An excellent course. Your course is exactly the kind of training that I need to introduce at my factory. Your presentation, skills and methods are excellent.

[Deon Van Der Merwe - General Manager - Navistar - Benoni - South Africa]

An excellent course. Lean Manufacturing is the most effective and value adding principle to any organisation.

[Cyprian Hlubi - First Line Manager - Nestlé - South Africa]

An excellent, really valuable course that is important for all organisations. I am really keen to go lean. Thank you.

[Matthew Cross - Industrial Engineer - The UWC Partnership - South Africa]

An excellent course, Carlo has opened my eyes with his energy-giving class.

[Estelle Vermaak - Site Manager - Rotek - South Africa]

An excellent course: Mamma Mia, we can go on again!

[Gert B. Kotze - Engineer - BHP Billiton Hotazel - South Africa]

An excellent course, the most valuable/enjoyable course I've done in a long time.

[H. J. Vlok - Project Manager - Grinaker-LTA Construction - South Africa]

An excellent course. Thanks, this will help us in the restructuring of Positions in the Company.

[Boet Greeff - Construction Manager - EPC Engineering & Projects Company - South Africa]

An excellent course. 1) It allowed opportunity to refocus on waste reduction and optimisation of resources utilisation 2) It will be invaluable if a construction site is identified and lean principles applied.

[Abdool Shaikh - Contract Director - Grinaker-LTA - South Africa]

An excellent course, very interesting and informative

[Elliot Mokgathe - Diphetogo Hi-tech Projects - South Africa]

An excellent course: new goals have been set, with basic innovative ideas can be done

[Pieter Van Heerden - Project Engineer - Grinaker-LTA - South Africa]

Will recommend this course to anyone that does Project Management

[Joseph Absai - Project Management Eng. - BP Namibia - Windhoek - Namibia]

An excellent course, I learnt a lot

[Lukas Petrus - Contracts Administrator - National Housing Enterprise - Windhoek - Namibia]

An excellent course, it was an eye opener

[Ernst Mathias - Manager, Projects - National Housing Enterprise - Windhoek - Namibia]

An excellent course: creating a work culture where people can own the final end product is good

[Alwyn Strauss - Senior Materials Engineer - Roads Authority - Windhoek - Namibia]

An excellent course. Thanks Carlo for introduce this concept to us. It would be great if it could be implemented at our Bank. You are an excellent presenter, serious, but with the right amount of fun and participant interaction. Wishing you all of the best in future. Hope to meet again soon.

[Lorelle Lordan - Recruitment and selection consultant, HR Dept. - Bank Windhoek - Windhoek - Namibia]

An excellent workshop, I really have learnt a lot. I think this message should be preached all over the world!

[Eric Simpeh - Quantity Surveyor - Global Construction - Namibia]

Excellent course: Carlo is brilliant and liberates the mind from the chains of traditional thinking that inhibits any real progress in improvement in the workplace.

[Yuri Mynhardt - QC Manager - Circuit Breaker Industries Ltd - Isando - South Africa]

read some recent testimonials from Malta

read all testimonials

| QUICK LINKS | ||

| Foreword | Training Modules: program and details of events | About Your Facilitators |

| From the Desktop of Dr. Carlo and Ing. Joseph | Quotes from Previous Delegates | Enquiries - Contact Us |

For administrative and technical enquiries please contact directly the workshop Leaders:

Dr. Carlo Scodanibbio

Tel. (+356) 2166 2115 - Mob. (+356) 7996 6056 - e-mail:

Ing. Joseph Micallef

Mob. (+ 356) 9982 2244 - e-mail: