scodanibbio.com

Carlo Scodanibbio Industrial & Business Consultant Lean Management Consultant |

public traininghome profile consulting training events contact |

scodanibbio.com

Carlo Scodanibbio Industrial & Business Consultant Lean Management Consultant |

public traininghome profile consulting training events contact |

www.scodanibbio.com/malta2015/

| QUICK LINKS | ||||

| Announcement | Programme | Expression of Interest - Enquiries | About Your Facilitators | Testimonials |

What does "lean" mean?

It means maximising the value of a product or service provided by an organisation to a customer while simultaneously minimising any form of waste present in the process that produces such product or service.

Lean Management is a philosophy and an operational discipline aiming at structuring an organisation (public or private) in a "lean" fashion.

The main targets?

1) Maximisation of value to the customer

2) Drastic elimination of waste in all processes (core and support) that generate value for customers

3) Elimination or drastic re-dimensioning of all those processes (and functions) that do not contribute to generate value to the customers

4) Minimisation of all times required to provide value to the customers

5) Zero defects, errors and non-conformities

6) Maximisation of employees', customers' and all stakeholders' satisfaction

While many organisations in the most industrialised countries worldwide are striving (or - at least - attempting) to undergo the lean road, what is happening in Malta in this regard? Little, not much - or, not enough - to the writers' opinion.

Lean principles were introduced in Malta over 20 years ago.

Carlo Scodanibbio contributed much in this regard, conducting over the years a number of lean training programs, addressed mostly to the manufacturing and project/construction sectors.

More advanced lean training programs were offered also in the past six years - recently, in a joint effort with Joseph Micallef.

What are our conclusions? Quite astonishing. Here are some comments expressed (regularly and repeatedly) by participating delegates:

"....we thought our enterprise was lean (after all, "lean" is not something out of this world), but it is not: now we can see how much waste is still lying around and how lacking is our value offer to our customers..."

"....we heard lean concepts from you many years ago - we understood them - we thought we had done well our homework... - to discover today we have done almost nothing.... - why?"

"....we love these lean principles, but we are not the right delegates in this course - it's our top management that should be sitting here today to listen to these messages...."

"....more than so much we cannot do in our operational area - it's the entire organisation, top-driven, that must become leaner...."

Yes, we thought we were "lean".

Lean is not a mission impossible: lean is basic common sense in business. Unfortunately, it gets easily mis-interpreted. If one asks top managers of private organisations if they think they are lean, most, if not all, will answer "yes, of course we are lean: we dedicate utmost care to our customers and we are organised in an extremely efficient way. It's even spelt out in our company mission statement - so we are lean.". Is it true?

Generally, it is not.

After preaching "lean" for so many years, there have been some "hits": a considerable number of Maltese Organisations, Private and Public, and from all Sectors, have actually undergone the lean road, some with remarkable results, some less. The number of "in-house" lean training initiatives conducted by the writers has increased, as well as the number of practical coaching interventions.

And yet, it's only a tiny fraction of the Maltese Business and Industrial Sector that has achieved some positive results through the deployment of lean practices.

Unfortunately, we have also observed (or known about) some partial failures.

Gloomy picture? Let's rather call it realistic, when observed from a Lean Management angle of view.

What is the problem? Organisations (or most of them) seem not to be able to cope with the complexity associated with the changing environment. The more pressure is put on them and the more corrective measures they try to adopt, the worse the results and the more the failures! It's the final coma of the first industrial revolution system, culture and mentality.

The only way out of this vicious circle is a revolution in the opposite direction. That's where Lean Thinking comes to the rescue.

The Second Industrial Revolution has started silently over two decades ago. But Malta seems so much attached to the principles, the strategies and the philosophy of the First one, invented by Adam Smith and Frederick Taylor long, long time ago: this is a considerable problem, because the First Industrial Revolution principles are rather "dated" - to say the least.

Many delegates attending our courses state that in a "Mediterranean" Country with a "Mediterranean" culture this state of affairs is just normal.

We definitely disagree with this statement. There is nothing wrong with a colourful and character-full Mediterranean culture, mentality and behaviour. To the contrary, it opens wide the doors to lean practices, so much in need for solid, creative thinking (the heart of Lean Thinking and Lean Management).

The strategy is to find a way to marry a "Mediterranean" style with Lean practices; which, however, is not impossible at all.

What is required to the purpose? Techniques (disciplines) - AND, most vital, cultural change.

Because - obviously - disciplines are disciplines, and tools are tools. They can be learnt, they can be obtained, they can be purchased.

Culture cannot. Modern, industrial, lean culture can only be "fabricated" in-house, within the organisation, by those concerned - starting from top management.

This is the hardest and trickiest part of the transition to "lean": changing culture. Unfortunately, the Smith & Taylor heritage is very heavy.

It has taken generations to digest and implement the principles of the first industrial revolution. It will take years or decades to digest those of the second one. Our industrial DNA is heavily polluted by traditional principles. We are still in love with the mass and batch production mentality, with traditional planning, supervision and control. With order and efficiency. With traditional strategic business planning. With traditional budgeting and cost accounting. With roles, authorities and job descriptions. With rules and procedures. Even hairdressers, retailers, and housewives (yes, housewives!) have fallen in love with mass production principles. The resistance to "lean" is and remains heavy.

We'll need to "slaughter", to change skin, like snakes do. We'll need to transform managers into coaches. We'll need to "fabricate" a new breed of people, people driven by value principles and not by "job" principles. People dedicated to re-conceive, improve and perfect the processes they handle, which they can understand, and for which they must become responsible. People who enjoy working and producing value, and draw satisfaction from it. New millennium craftsman in their workshops. New millennium traders in their shop. In strict contact with their customers. Empowered People to whom pride and professional and work dignity, usurped by over a century of labour division and top-control practices, will finally be given back. People who can think: lean (that's why the name: Lean Thinking).

It will take time. With everybody's commitment, much less.

And the time to go lean is NOW.

In line with the above, Dr Scodanibbio and Ing Micallef have ready plans for another set of public training activities to be organised in Malta during 2015, starting in June 2015 - as well for in-house training interventions.

Two specific training programs have already been scheduled (see below for details under Programme/Calendar):

- A 1-day brand new for Malta Lean Scenario Planning, revolutionary, and really shocking (June 2015).

- A 2-day brand new for Malta Lean Laboratory Management, a MUST for key Personnel of any Lab of any sort (early July 2015).

Other Lean training courses/workshops on offer for 2015 include (but are not limited to) those listed in the Expression of Interest fill-out form below. These workshops may be presented as public or "in-house" training.

Expressions of Interest are invited from all business sectors, public or private, who are keen in participating in this year’s events. The organisers shall consider all suggestions brought forward, whilst they are also available for facilitating in-house pilot projects to demonstrate the benefits of lean and quality improvement programmes.

In-house courses can take place on dates set by mutual agreement.

We invite large participation both from the Private and Public sectors.

Dr. Carlo Scodanibbio and Ing. Joseph Micallef

| QUICK LINKS | ||||

| Announcement | Programme | Expression of Interest - Enquiries | About Your Facilitators | Testimonials |

PLEASE NOTE: this Web Page is for historical record only.

Therefore all Forms below - as well as the Online Registration/Enrolment Forms - are no longer active.

| 'MALTA 2015 LEAN MANAGEMENT TRAINING PROGRAMME': Scheduled Events | |||

| Training Module: title, date, price, venue, broad topics, duration, target audience | Detailed Brochure | Registration Form | Register Online |

|

Event 01 - LAUNCHING CONFERENCE/WORKSHOP: LEAN SCENARIO PLANNING

For Top/High-Level Managers/Directors and Business Strategists of Private (all Sectors) and Public Organisations. Date: 23rd June 2015 Price: Euro 260/delegate before "fast-settlement" discounts. Venue: TBA - High-Class Venue, Malta. A 1-day open and interactive conference and workshop addressed to sensitise attending delegates on the limitations of traditional "strategic planning" and traditional "budgeting" in a world changed to such an extent that new, wider-horizon interpretations of business phenomena are required. Understanding global phenomena, taking into due consideration Lean principles and being capable of capturing significant - even faint - signals as early as possible is now a necessity for any organisation willing to tackle the future in a conscious mode. |

Click here for a printable pdf Brochure

Click here for a printable pdf Timetable |

Click here for a printable pdf Registration Form | Click here to enrol online |

|

Event 02: LEAN LABORATORY MANAGEMENT An intensive two-day course/operational workshop on how to increase efficiency, effectiveness and overall performance in any-type Laboratory environment - for key Laboratory Personnel from Labs of any type and size (QC Labs, Medical/Hospital Labs, Pharmaceutical and Food industries Labs, Educational Labs, supplies acceptance Labs, in-process Labs etc.) - Private and Public Organisations. Dates: 7-8 July 2015 Price: Euro 490/delegate before "fast-settlement" and "group" discounts. Venue: TBA - High-Class Venue, Malta. |

Click here for a printable pdf Brochure

Click here for a printable pdf Timetable |

Click here for a printable pdf Registration Form | Click here to enrol online |

|

More Events to be released soon: check this page regularly for updates! |

|||

| QUICK LINKS | ||||

| Announcement | Programme | Expression of Interest - Enquiries | About Your Facilitators | Testimonials |

For any enquiry please contact directly the workshop Leaders:

Dr. Carlo Scodanibbio

Mob. (+356) 7996 6056 - e-mail:

Ing. Joseph Micallef

Mob. (+ 356) 9982 2244 - e-mail:

You may express interest for the 2015 program and also request further clarifications about by filling the form below:

(fields marked * must be filled)

| LEAN MANAGEMENT TRAINING PROGRAM - Malta 2015 - Other Events | ||

| Training Module: title, short description, duration, target audience |

Expression of Interest Public Course |

Expression of Interest "In-House" Course |

|

Event 03 - LEAN MANAGEMENT PRINCIPLES FOR TOP MANAGEMENT For Top Managers/Directors of Private (all Sectors) and Public Organisations. A 1-day open and interactive conference addressed to enable attending delegates to "see" wasteful areas and value-loss points in their organisation and to sensitise the audience on the necessity of deploying lean practices organisation-wide; while launching, in parallel, a continuous cultural change management project. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 04: THE LEAN ENTERPRISE (OPERATIONAL LEAN MANAGEMENT) For High-Level Operational Managers of Private (all Sectors) and Public Organisations. A 3-day event addressed to: enable attending delegates to "see" wasteful areas and value-loss points in their organisation - illustrate operationally lean techniques and disciplines to be deployed for the lean transition - give practical hints on how to structure the lean re-engineering project organisation-wide - convey broad operational principles of continuous, lean performance improvement - and to sensitise the audience on the necessity of undergoing a solid cultural change and transmitting effective messages in this regard organisation-wide. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 05: LEAN MANAGEMENT: OPERATIONAL PRINCIPLES FOR THE SERVICE AND HOSPITALITY INDUSTRY For High- and Middle-Level Managers of Private and Public Organisations providing general and hospitality services (all Service Establishments - all Service Providers - Hospitality Industry Operators - etc., including services such as: health, telephony, insurance, financial, tourism, tour operator, car-hire, hoteliers, airport, catering, airline, shipping & forwarding, export/import, retailing, etc.). A 2-day event addressed to: enable attending delegates to "see" wasteful areas and value-loss points in their organisation - illustrate operationally lean techniques and disciplines to be deployed for the lean transition, targeting at maximising output value to customers, in a error-free and fastest time mode, while minimising processing waste - give practical hints on how to structure the lean re-engineering project organisation-wide - convey broad operational principles of continuous, lean performance improvement - and to sensitise the audience on the necessity of undergoing a solid cultural change and transmitting effective messages in this regard organisation-wide. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 06: CREATIVE THINKING: THE "ULTIMATE" LEAN RESOURCE For High and Middle Level Managers of Private (all Sectors) and Public Organisations. A 3-day event. Creative Thinking is the heart of Lean Thinking. This course will illustrate very interactively all main creative techniques, methods and tools (from Brainstorming onwards) to be deployed in: A) Creative Problem Solving B) Continuous Improvement C) Search for Opportunities D) Change and Innovation. Particular care will be dedicated to creative work in team. This course is a "must" for all managers of any size and type of organisation. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 07: LEAN MANAGEMENT: WAYS TO SUCCEED, WAYS TO FAIL For Top, High and Middle Level Managers of Private (all Sectors) and Public Organisations. A 1-day event, which will illustrate in detail all necessary conditions and prerequisites that must be fulfilled and complied with in order to launch an Organisation-wide Lean Management project in the most appropriate way - sustain it in all phases of its lifecycle - and make it produce the wanted results. Unfortunately, even one non-compliance with those vital conditions may be sufficient to generate failure bacteria - as it will be shown with relevant case studies. A must-training for any organisation willing to embark into a Lean Management project or in the process of launching it. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 08: STUPIDITY, A MAJOR OBSTACLE TO LEAN

For Top, High and Middle Level Managers of Private (all Sectors) and Public Organisations. A 1-day event. Human stupidity is more diffused than most people think or believe. Stupid actions or initiatives, undertaken at individual-, group-, organisation- and even Country-level take place extremely frequently and represent a major obstacle to better performance - at any level. This course targets at: supplying a simple and extremely powerful key of interpretations of human actions, in order to grasp as rapidly as possible the impact associated with stupidity - showing why and how in "traditional" organisations stupidity may cause detrimental effects to real improvement and better performance - illustrating stupidity under the Lean angle of view - and empowering attending delegates to prevent stupid initiatives from happening, or at least repeating - jeopardizing as such a Lean Project. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 09: TOTAL QUALITY MANAGEMENT FOR THE LEAN ENTERPRISE For High and Middle Level Managers of Private (all Sectors) and Public Organisations. A 3-day event. This will be a most comprehensive course illustrating the "quality" state of affairs in a lean environment. Traditional and modern QC and QA methods and techniques will be presented in detail, highlighting the pro's and the con's of each of them versus the requirements of the Lean philosophy. Particular attention will be given to the ISO 9001 Quality Management system under the lean angle of view. The course will be most beneficial to Quality, Marketing, R&D, Procurement and Operations personnel from all size and type of organisations. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 10: LEAN MANUFACTURING FOR SMEs For High-, Middle- and Frontline-level personnel (Operations - Production Planning - QA - Maintenance - Procurement - Logistics - Materials Management - etc.) in the Manufacturing Industry A 3-day event. Targets: understand "waste" and "value-adding" in manufacturing operations; eliminate waste, maximise output value - understand "push" and "pull" production methods and see the difference between "batch" and "single-piece" production - learn the principles and techniques of lean, continuous flow manufacturing and "cell" manufacturing - understand the "lean" disciplines: 5S and workplace management; mistake-proofing tools for zero-defects; basics of quick set-up; basics of TPM and Autonomous Maintenance; Value Stream Mapping; and others - understand the necessity of a cultural change to take place in parallel with the deployment of lean disciplines. Effective for any size Manufacturing organisation, this course will be particularly beneficial to owners/managers of micro and small enterprises. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 11: LEAN PRODUCTION PLANNING AND VALUE CHAIN MANAGEMENT For Middle- and Frontline-level personnel (Operations - Production Planning - IT - Procurement - Logistics - Materials Management - etc.) in the Manufacturing Industry (both: "make-to-stock" and "make-to-order"). A 3-day event. Targets: understand in full the difference between "traditional" and "lean" production planning - explore the available planning methods (MRP - MRPII - CRP - ERP - etc.) and see pro's and con's - touch the consequences of inadequate, "push" planning and its repercussions all along the supply and demand chains - see the advantages of lean "pull" planning methods - understand the effects of non appropriate deployment of the Kanban method - know about the inadequacies of "traditional" planning SW or the effects of using inappropriately "modern" planning SW - learn how to assure a continuous materials flow all along the value chain and how to best integrate your production plan for needed flexibility and appropriate capacity with a style suited to the turbulent and volatile times ahead - learn specific planning techniques for "make-to-order" (contract) manufacturing. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 12: LEAN MANUFACTURING: WAYS TO SUCCEED, WAYS TO FAIL For Top, High and Middle Level Managers of Manufacturing Companies. A 1-day event, which will illustrate in detail all necessary conditions and prerequisites that must be fulfilled and complied with in order to launch a Lean Manufacturing project in the most appropriate way - sustain it in all phases of its lifecycle - and make it produce the wanted results. Unfortunately, even one non-compliance with those vital conditions may be sufficient to generate failure bacteria - as it will be shown with relevant case studies. A must-training for any Manufacturer willing to embark into a Lean Manufacturing project or in the process of launching it. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 13: TOTAL PRODUCTIVE MAINTENANCE AND LEAN PLANT/ASSETS MANAGEMENT For High- and Middle-level managers (Operations - Maintenance - Plant Management - Plant Engineering - QA - etc.) in the Manufacturing Industry and Continuous Process Industry A 3-day event. Targets: explore all available maintenance disciplines (Reactive, Preventive, Predictive, Reliability-Centred, RBM/RBI, IPF, Shut-Down & Outage Maintenance, etc.) and discover the best-suited maintenance regime for your operations - understand in detail TPM as a plant management philosophy, an operational maintenance discipline and a cultural change catalyst, and grasp its operational tools - "see" where waste hides in "traditional" maintenance activities and learn ways to eliminate it - make maintenance works "flow" and produce valid, error-free results in less time - learn how to plan maintenance activities in a lean fashion - understand the revolutionary principles behind Lean Plant and Assets Management. Although dedicated to the Manufacturing and Continuous Process industries, this course will be particularly beneficial to any heavily mechanised/automated type of operations, including large Construction Companies, highly IT-dependent Service Providers, Power Generation, etc. as well as to Maintenance Contractors, Public Works Departments and Municipalities. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 14: TOTAL PRODUCTIVE AND AUTONOMOUS MAINTENANCE FOR PLANT/MACHINE OPERATORS For Frontline Maintenance/Operations Personnel (Plant & Machine Operators, Maintenance/Service Technicians/Fitters) as well as Supervisors and Foremen in the Manufacturing Industry and Continuous Process Industry A 1-day event. Targets: understand the TPM discipline and its approach to Plant/Machinery care - learn basic principles of Autonomous Maintenance as best medicine to prevent breakdowns and fight machine idling, minor stoppages, reduced speed functioning, and output defectiveness - understand the new relationship style between Production and Maintenance and how to undergo painless integration between the two functions - enhance overall sense of responsibility and accountability of all those working next to or around plant and machinery. Although dedicated to the Manufacturing and Continuous Process industries, this course will be particularly beneficial to any heavily mechanised/automated type of operations, including large Construction Companies, highly IT-dependent Service Providers, Power Generation, etc. as well as to Maintenance Contractors, Public Works Departments and Municipalities. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 15: ACHIEVING QUICK CHANGE-OVER For Frontline Set-up, Maintenance and Operations Personnel (Set-up Technicians, Plant & Machine Operators, Maintenance/Service Technicians/Fitters) as well as Supervisors, Foremen and Middle Level Managers (Production, Maintenance, Tool Shop, QA, etc.) in the Manufacturing Industry A 1-day event. Targets: learn in detail operational principles of quick change-over and set-up (line change-over, machine set-up, re-tooling, changing process parameters, etc.) under the Lean approach - understand the organisational and technical methods suited to reduce drastically set-up time in an error-free mode - grasp the concepts of the cultural change associated with the deployment of the methods - understand the continuous improvement approach to set-up time reduction up to zero seconds. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 16: LEAN PROJECT & CONSTRUCTION MANAGEMENT For Senior & Middle-Level Managers (Operations Managers, Project Managers, Contract Managers, Proposal Managers, Project Planners and Controllers, Site Managers, etc.) from the Construction and Project-driven industry (turn-key, industrial installations, EM contracts, etc.), as well as professional Project Managers, Architects, Engineers and Senior Project Personnel from the Public Works sector and Municipalities. A 3-day event. Targets: learn in detail the "traditional" Project Management discipline and its main Planning and Control techniques (WBS, PERT/CPM, Earned-Value, Risk Management, etc.) - see the deficiencies and flaws of the same - understand in detail the Lean approach to managing projects, engineering, architectural and construction works, and "see" the waste that hides in the same - learn how any type of project work can be made flow, work-package after work-package, in a waste-less and error-free fashion, thus minimising the overall throughput time - learn lean planning techniques and the "last planner" approach - grasp the lean approach to multi-project management to prevent any bottleneck in any project - understand the necessity of associating a solid cultural change in project personnel at all levels while deploying lean tactics. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 17: LEAN PLANNING AND LEAN PROJECT MANAGEMENT FOR THE MANUFACTURING INDUSTRY For Senior & Middle-Level Managers (Operations, QA, Plant, Engineering, R&D, Product Development, etc.) from the Manufacturing Industry. A 2-day event. Targets: learn the "traditional" Project Management discipline and its main Planning and Control techniques (WBS, PERT/CPM, Earned-Value, Risk Management, etc.) - see the deficiencies and flaws of the same - understand in detail the Lean approach to managing projects such as new installations, plant alterations, new product development, and "see" the waste that hides in the same - learn how any type of project work can be made flow, work-package after work-package, in a a waste-less and error-free fashion, thus minimising the overall throughput time - learn lean planning techniques and the "last planner" approach - grasp the lean approach to multi-project management to prevent any bottleneck in any project. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 18: LEAN PLANNING AND LEAN PROJECT MANAGEMENT FOR THE SERVICE INDUSTRY For Senior & Middle-Level Managers (Operations, QA, Plant, IT, R&D, New Service Development, etc.) from the Service Industry. A 2-day event. Targets: learn the "traditional" Project Management discipline and its main Planning and Control techniques (WBS, PERT/CPM, Earned-Value, Risk Management, etc.) - see the deficiencies and flaws of the same - understand in detail the Lean approach to managing projects such as new installations, new outlets, new branches, refurbishments, alterations, new service development and launch, etc. and "see" the waste that hides in the same - learn how any type of project work can be made flow, work-package after work-package, in a a waste-less and error-free fashion, thus minimising the overall throughput/completion time - learn lean planning techniques and the "last planner" approach - grasp the lean approach to multi-project management to prevent any bottleneck in any project. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 19: LEAN CUSTOMER CARE: OPERATIONAL PRINCIPLES FOR FRONTLINE PERSONNEL IN THE SERVICE AND HOSPITALITY INDUSTRY For Frontline Personnel & Supervisors of Private and Public Organisations providing general and hospitality services (all Service Establishments - all Service Providers - Hospitality Industry Operators - etc., including services such as: health, telephony, insurance, financial, tourism, tour operator, car-hire, hoteliers, airport, catering, airline, shipping & forwarding, export/import, retailing, etc.). A 1-day event addressed to: enable attending delegates to "see" wasteful areas and value-loss points in their daily activities, and provide hints to eliminate both deficiencies - illustrate operationally lean techniques to adopt in any contact with clients (personally, telephonically, etc.) in order to maximise service output value to customers, in a error-free and fastest time mode, while minimising processing waste - instil concepts of lean behaviour and attitude - convey operational principles of continuous, lean service performance improvement and of opportunities generation. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 20: TOTAL EMPLOYEE INVOLVEMENT & LEAN HUMAN RESOURCES MANAGEMENT For High and Middle Level Managers of Private (all Sectors) and Public Organisations. A 2-day event. There is no way to be Lean without deep and active involvement of all personnel. This course will present the most modern approaches to people management in a Lean environment. It will prove that people are better, more flexible, more adaptable, more ready to take up responsibilities, more curious to learn and willing to grow than most managers believe. It will also show the very simple path to better and even excellent people performance if the right conditions are created. This course is a "must" for all managers of any size and type of organisation. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 21: LEAN KAIZEN (CONTINUOUS/SYSTEMATIC PERFORMANCE IMPROVEMENT IN THE LEAN DIRECTION) For High-Level Operational Managers of Private (all Sectors) and Public Organisations. This is a 2-day event addressed to: enable attending delegates to "measure" the present performance level organisation-wide through KPIs - identify and define the "gap", and set Lean Kaizen improvement targets - structure the Continuous Improvement project with rational priorities and a logical plan of action - illustrate in broad detail lean techniques and disciplines to be then deployed operationally by their collaborators during the lean implementation stage. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

|

Event 22: OPERATIONAL LEAN KAIZEN: THE TOOLS AND TECHNIQUES For Middle-Level and Frontline Managers of Private (all Sectors) and Public Organisations. A 32-Hrs event. Targets: illustrate in great detail and very interactively all main tools and techniques to be deployed operationally in a continuous, systematic performance improvement program by those concerned (middle-level and frontline managers). The tools and techniques include (but are not limited to): 5S and Workplace Management - Pareto Diagram/ABC Analysis - Cause-Effect (Ishikawa) Diagram - Scatter Diagram - Control Charts - Flow Charts - Tree Diagram - Matrix Diagrams - Relations Diagram - Affinity Diagram - Cedac - Problem Solving - P-M Analysis - the Poka-Yoke approach - etc. as well as specific Lean Thinking tools such as 5W2H - 5Why - Communication Circle - Spaghetti Diagram - Value Stream Mapping, etc. Specific training in effective Team-Work will also be provided. |

Tick if of interest (Public Course) Number of Delegates: |

Tick if of interest (In-House Course) Number of Delegates: |

If you have expressed interest for any of the training events listed above, kindly let us have your details by completing the form below:

(fields marked * must be filled)

| Name* | Surname* | ||

| Company* | Position* | ||

| E-Mail Address* | Country* | ||

| Telephone | Fax |

Thank you - your Expression of Interest and/or enquiry will be acknowledged soonest.

| QUICK LINKS | ||||

| Announcement | Programme | Expression of Interest - Enquiries | About Your Facilitators | Testimonials |

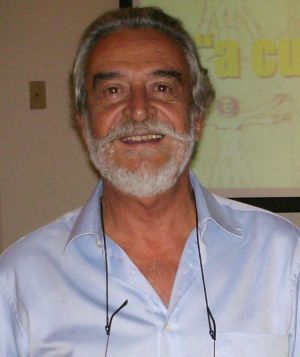

Carlo Scodanibbio, born in Macerata (Italy) in 1944, holds an Italian doctor degree in Electrical Engineering (Politecnico di Milano - 1970).

Carlo Scodanibbio, born in Macerata (Italy) in 1944, holds an Italian doctor degree in Electrical Engineering (Politecnico di Milano - 1970).

He has over 44 years of experience in Plant Engineering, Project Engineering and Project Management, as well as Industrial Engineering and Operations Management.

Free-lance Consultant since 1979, he has worked in a wide spectrum of companies and industries in many countries (Southern Africa - Italy - Cape Verde - Romania - Malta - Cyprus - Lebanon - Mauritius - Malaysia - Kenya - India - Saudi Arabia - Seychelles), and operates as an Independent Professional Consultant and Human Resources Trainer to industry.

His area of intervention is: World Class Performance for Small and Medium Enterprises in the Project, Manufacturing, and Service sectors.

His favourite area of action is: the "lean" area.

He has co-operated, inter-alia, with the Cyprus Chamber of Commerce, the Cyprus Productivity Centre, the Malta Federation of Industry, the Malta Chamber of Commerce and Industry, the Mauritius Employers' Federation, the Romanian Paper Industry Association, the United Nations Industrial Development Organisation, the Seychelles Chamber of Commerce and Industry and the University of Cape Town.

His workshops and seminars, conducted in English, Italian and French, have been attended by well over 18.000 Entrepreneurs, Managers, Supervisors and Workers. They feature a very high level of interaction, and are rich in simulations, exercising and real case studies. The approach is invariably "hands-on" and addressed to immediate, practical application.

Joseph Micallef graduated in electrical engineering from the University of Malta in May 1992. He has been involved in the manufacturing industry since 1990. Initially starting his career within the medical devices and plastics processing manufacturing sector, he later moved on within the electronics manufacturing sector.

Joseph Micallef graduated in electrical engineering from the University of Malta in May 1992. He has been involved in the manufacturing industry since 1990. Initially starting his career within the medical devices and plastics processing manufacturing sector, he later moved on within the electronics manufacturing sector.

Throughout his career, Joseph has had experiences in a variety of industrial and automation processes, research and development projects, various manufacturing processes and occupied senior technical and management roles in research and development, process control, quality management, occupational health safety and business process management. Joseph has occupied senior management positions in the plastics, medical devices and electronics industries over a career spanning more than 21 years.

Apart from his broad industrial involvement, Joseph has also paralleled his experience through consultancy projects since the year 2000.

Assignments undertaken through freelance activities include an even broader range of industrial and manufacturing enterprises, service sectors (insurance, financial institutions, real estate, project oriented organisations, construction business, logistics services (air/land/sea), food industry, NGO’s, utilities, public sector, etc.), project management assignments, operations strategic reviews, etc.

Joseph regularly organises and facilitates a number of training workshops and presentations including seminars and conferences to top executives.

Joseph's career spreads primarily in Malta, but he has been assigned several projects and delivered training in various countries within Europe (UK, Scotland, Belgium, France, Finland, Italy), the US (Jacksonville, Houston) and the Middle East (Egypt, UAE, Oman).

Ing. Joseph Micallef is a corporate member of a number of institutions. In particular he is registered Chartered Engineer with the Engineering Council (UK) - C.Eng., corporate member in the Institution of Engineering and Technology (UK) - MIET, European engineer through FEANI - Eur.Ing., and warranted member within the Chamber of Engineers (Malta) and sits on the Malta Engineering Board.

| QUICK LINKS | ||||

| Announcement | Programme | Expression of Interest - Enquiries | About Your Facilitators | Testimonials |

This has been a very interesting introductory session on various world class performance topics. Carlo's delivery is unique!!

[Edward Saguna - Plant Maintenance and Project Engineer - De La Rue - Malta]

An excellent course, thanks for the very interesting material!

[Dorianne Debattista Grech - Senior Executive Relationship Management - Malta Enterprise - Malta]

An excellent course, extremely enjoyable and interesting.

[Orietta Mallia - Senior Executive - Malta Enterprise - Malta]

An excellent course, I never attended such an interesting one.

[Mark Meilak - Operations Engineer - Multigas - Malta]

An excellent course: seeing the obvious may sometimes be the most challenging of tasks....

[Ray Scerri - QC Manager - Simonds Farsons Cisk - Malta]

An excellent course, that explained Lean and its importance by showing movies with facts that prove the success of companies who adopted lean!

[Noel Attard - Process Engineer - Seifert MTM Systems - Malta]

An excellent course, highly recommended.

[Kevin Vella - Support Manager - Actavis Ltd - Malta]

An excellent course, definitely value for money, and good eye-opener to identify company problematics.

[Karl DeGaetano - TQM Officer - Carlo Gavazzi Ltd - Malta]

An excellent course. Overall it was an injection to improve and to try go lean. You have managed to convince me that lean is the only way.

[Michael Grech - Factory Manager - Foster Clark's - Malta]

An excellent course, very well planned for the time used, well illustrated, and gave good examples.

[Duncan Mangion - Process FLM - De La Rue - Malta]

An excellent course, very well organised - keeps you there at all times.

[Christine Grima - Trainee Engineer - Trelleborg - Malta]

Excellent course, with direct point covered in an exceptional manner through case study, theoretical information and workshops.

[Franz Joseph Cauchi - QC Team Leader - Actavis Ltd - Malta]

An excellent course - after it my performance will definitely be more lean.

[Gary Zerafa - Shift Manager - Actavis Ltd - Malta]

An excellent course, very well prepared and delivered. Impressive database of case studies and practical examples.

[Maurizio Cappello - Engineering Manager - Actavis Ltd - Malta]

Great course, mind opener!

[Claire Agius - Dept. Manager, QC - Actavis Ltd - Malta]

I have once again benefited greatly from this excellent course, and I would recommend it to any person, especially top management.

[Neal Borg - Graduate Trainee - Trelleborg - Malta]

A very good, interesting course, humour kept it alive. Thank you.

[Kevin Mennie - Front line manager - Trelleborg - Malta]

An excellent course, very good content, new ideas on how to be better

[Noel Psaila - Director, Engineering - Mater Dei Hospital - Malta]

An excellent course. I thought I was lean... But I am way behind! Now I have watched myself and have tools to improve!

[Paul Simon Zammit - Electrical Engineer - Mater Dei Hospital - Malta]

An excellent course. The bug has been transferred!! Will make sure it multiplies!

[Pierre Dalmas - Packaging Manager - Simonds Farsons Cisk - Malta]

Very well done to Dr. Carlo - good understandable flow throughout the course material. Thanks.

[Simon Caruana - Site Manager - Mekanika - Malta]

Lean, excellent

[Sasha Antunovic - Electrical Engineer - Mekanika - Malta]

An excellent course. A better defined set of management principles to follow and believe in.

[Stephen Mifsud - Technical Services Manager - Simonds Farsons Cisk - Malta]

An excellent course. I was impressed by the tutor's competence on the subject.

[Marnick Gatt - Maintenance Foreman - Simonds Farsons Cisk - Malta]

The course changed my point of view into a leaner approach to work environment.

[Sean Azzopardi - Technical Foreman - Simonds Farsons Cisk - Malta]

An excellent, very well presented course.

[Arthur Napier - DPA/Electronics - Gozo Channel Co. - Malta]

An excellent course, very well done!!! Excellent training method, especially the way you distributed your topics and the timing of the exercises!!! You came up with an exercise as soon as we tended to drift off!!

[Melanie Bugeja - Finance Director - The Catalogue Co. Ltd - Malta]

An excellent course, very well prepared and delivered.Keep it up.

[Joseph Dingli - Accountant, Sole Practitioner - Malta]

Recommended course for managers and decision makers to review and re-evaluate their practices, style and disciplines.

[Michael Warrington - Group Finance Director - AX Holdings Ltd - Malta]

An excellent course, very well presented, and reinforced my determination in our lean project. Your wide practical experience is evident. Compared with my experience so far with Lean principles, your stress on the People aspect is something which I fully agree with. Well done and thank you!

[Ruben Cuschieri - General Manager - Seifert-MTM Systems - Malta]

An excellent course. Very good presentation. Very effective the video productions to see waste.

[Darren Bondin - Assistant Accountant - Corinthia Construction Overseas Ltd - Malta]

An excellent course. I think it has been a great experience to learn and re-visit certain concepts which, when applied, are valid for multi-functional and commercial sectors.

[Ray Sladden - Group Finance Director - Tumas Group - Malta]

An excellent course. Very interesting videos linked to the subject.

[Charles Xuereb - Chief Financial Officer - Simonds Farsons Cisk Ltd - Malta]

An excellent course, very good presentation.

[James Vella - Administrative Supervisor - Multigas Ltd - Malta]

An excellent course, very excellent and professional delivery balanced with very good animations, videos and activities. This course triggers our dormant "brains". Keep it up.

[Saviour Zammit - Technical Manager - Multigas Ltd - Malta]

An excellent course. Very good presentation techniques. Very difficult for one presenter to keep people captivated for 3 whole days. Material very relevant.

[Margot Pisani - General Manager - Sanofi Aventis Malta Ltd - Malta]

An excellent course. Thank you very much for such a well planned and delivered program. I particularly enjoyed the movies and case studies as these helped me understand the concepts better and in a way I will remember them more easily.

[Claudine Spiteri Cefai - Chief Financial Officer - Sanofi Aventis Malta Ltd - Malta]

An excellent course, intensive but fun thanks to a good delivery of the subject by Dr. C. Scodanibbio. Look forward to implement at least a few of what was communicated.

[Kevin Callus - Operations Manager - AX Holdings - Malta]

An excellent course. As an NLP Practitioner, I operate by the theory of "Perception is Projection", "Being at cause" and total empowerment of individuals, leading and managing by inspiration and holistic respect. All you said confirmed and added to my beliefs and tought me more. Thank you.

[Kathleen Vella - Performance Coach/NLP Trainer - Tuning Fork Ltd. - Malta]

An excellent course. The TEI concept is a very good concept and should be applied to all companies. I'm glad to have been part of this course. Lecturer was simply excellent!

[Darren Micallef - Financial Controller - Where's everybody - Malta]

I have found the course to be excellent as marked and sets very high, idealistic targets. Having said that I hope that persuasion + convincing of managers will enable part application of what has been learnt.

[Marina Sceberras - Executive Secretary - MCAST - Malta]

An excellent course, very good delivery

[Roderick Scotto - Project Manager - Trelleborg - Malta]

An excellent course: the presentation style is unique and first-class

[André Spiteri - OperationsManager - Methode Electronics - Malta]

An excellent course: very well prepared and delivered - thanks!

[Mark Mifsud - Development/Tooling Manager - Toly Products - Malta]

An excellent course: very good presentation and case studies

[Keith Dingli - Quality Sponsor - Adpro-Instruments Ltd - Malta]

An excellent course, well done. Excellent presentation supported with practical and easy to follow examples in an entertaining way.

[Emidio Friggieri - General Manager - Adpro-Instruments Ltd - Malta]

An excellent course, very informative.

[Mario Debono - Director - Maypole - Malta]

An excellent course, very professionally delivered. Speaker steals your attention. No boredom and kept light with pertinent humour.

[Marco Spiteri Binnett - Director & Manager - Sullivan Maritime Ltd - Malta]

Very happy with the course and the delivery.

[Joseph Vassallo - Business Development Manager - Malta Enterprise - Malta]

An excellent course, well organised and very professionally presented - thanks to Dr. Carlo Scodanibbio

[Manuel Portelli - Manager - Sullivan Maritime Ltd - Malta]

An excellent course, very well presented. Very satisfied. Time well spent and very good investment for the future of my career. Well done!!

[Jesmond Zammit - Commercial Manager - Sullivan Maritime Ltd - Malta]

An excellent course. An eye-opening experience with much that can be applied in practice.

[Ian Camilleri - Financial Controller - Salvo Grima Group - Malta]

An excellent course, well presented - distributed the message

[Keith Dingli - Quality Supervisor - Adpro-Instruments Ltd. - Malta]

An excellent course. It made me think more about the way we operate + how to add value to our clients + company.

[Nicholas Saliba - Group Administration & HR Manager - AX Holdings Ltd. - Malta]

An excellent course, lean and concise.

[Marcus Muscat Baron - Engineering Manager - Dedicated Micros - Malta]

An excellent course. What I appreciated more as compared to other lean exposures is the drive towards getting to the roots of this philosophy rather than just principles.

[Conrad Pace - Head of Operations - Prominent Fluid Controls Ltd. - Malta]

An excellent, top notch, very well presented course. Thanks & well done!

[André Spiteri - Operations Manager - Hetronic Malta Ltd. - Malta]

An excellent course, very well presented, with interesting movies which are realistic.

[Brian Muscat - Operations Manager - Multi Packaging - Malta]

Overall I am very happy to have attended this course. All subjects were already known to me but I heard them from a different perspective. Thank you.

[Marvin Abela - Head of Lean Manufacturing - Methode Malta - Malta]

An excellent course: it makes you look at things from a different, better perspective.

[Sara Buttigieg - Business Development Executive - Malta Federation of Industry - Malta]

An excellent course. It is the cultural change that may prove to be the most difficult but we shall try.

[Joseph Farrugia - NPD Executive - Stainless Steel Products Ltd. - Malta]

An excellent course. I was introduced to a totally new way of thinking and this will improve my performance not only at the place of work but also in the general activities performed daily.

[Neal Borg - Project Leader - Hetronic Malta - Malta]

An excellent course. Very interesting philosophy, and gets mind thinking and looking for waste.

[Robert Bonavia - Operations Manager - Trelleborg Sealing - Malta]

An excellent course. It was an eye-opener to concentrate on what is actually "value-adding".

[Gerald Portanier - Operations Manager - Trelleborg Sealing - Malta]

An excellent course, enjoyed it a lot. If everybody had the opportunity to attend, industry will make a big step forward.

[Chistopher Borg - Engineer - De La Rue - Malta]

An excellent course. Coming from a lean-sigma environment, I found the course very comprehensive, well presented with clear objectives and exercises. Well done to the presenter and FOI for such an initiative.

[Patrick Cachia - Production Manager - Actavis Ltd. - Malta]

An excellent event.. looking forward for some more workshops sessions

[Roderick Farrugia - After Sales Manager - Alberta Fire & Security - Malta]

An excellent event - very well done!

[Joseph Bonello - Projects Manager - Alberta Fire & Security - Malta]

An excellent event.

[Godfrey Chircop - Services Manager - De La Rue Ltd - Malta]

Look forward to other sessions

[Duncan Mallia - Integrated Solutions Manager - Enemalta - Malta]

An excellent event, very well presented and backed up with experience.

[Ing. Charles Grixti - Manager, Distribution - Enemalta - Malta]

An excellent event, well done!

[Brian Sciberras - Quality Leader - Hetronic Malta Ltd - Malta]

It has been a truly interesting event which I will use in my life and place of work. Well done!!

[Roderick Abela - Production Leader - Hetronic Malta Ltd - Malta]

An excellent event.

[Mark Bruno Olivier - Business Process Improvement Manager - Transport Malta - Malta]

An excellent event.

[Ethel Baldacchino - Executive, Business Process Improvement - Transport Malta - Malta]

An excellent event.

[Charles Xuereb - Chief Financial Officer - Simonds Farsons Cisk - Malta]

An excellent event, very impressive presentation delivery skills!

[Ing. Alexia Grech - RTOI Consultant - Malta Enterprise - Malta]

An excellent course - a very good immersion into Lean Thinking. The course stimulates thought and makes one reflect upon the operations of one's enterprise.

[Dr Dino Mangion - Plant Manager - Medichem Manufacturing - Malta]

An excellent course. An overall positive experience with a lot of food for thought.

[Maurizio Cappello - Department Manager - Actavis Ltd - Malta]

An excellent course, inspiring principles of management. I will try to implement as much as possible in my own department and elsewhere after.

[Stefan Mohnani - Head of R&D - Medichem Manufacturing - Malta]

An excellent course.

[Tonio Polidano - Procurement Manager - MITA - Malta]

This course was very interesting, useful and most of all pertinent to today's industrial scenario.

[Ing. Oliver Fsadni - Production Manager - Andrew Feeeds (Malta) - Malta]

An excellent and innovative course.

[Ryan Brincat - Head of Maintenance and Engineering - Medichem Manufacturing - Malta]

An excellent course.

[Paul Gatt - Production Manager - General Soft Drinks Co. - Malta]

An excellent course. My compliments to Carlo for clearly showing that Lean is the way forward.

[Andrew Demarco - Engineering Manager - De La Rue - Malta]

An excellent course. Very sound concepts, presentation with excellent case studies to back up the theoretical part.

[Maurizio Cappello - Department Manager - Actavis Ltd - Malta]

An excellent course, very well presented, and valuable material and visuals and sound has much more impact, especially video. If your other courses are in a similar vein with different content we will be interested!!

[Peter Pace - BPR Analyst - Enemalta - Malta]

A very well delivered course, especially the workshop sessions.

[Silvio Agius - Quality Manager - Transport Malta - Malta]

An excellent course. This training should be delivered in some way to schools and educational institutions.

Well done.

[Keith Dingli - Projects Co-ordinator - MSC Malta - Malta]

An excellent course. It is always great being re-assured by like minded enthusiasts that I am not crazy.

[Debbie Gatt - Lean Coach, BPR Dept. - Enemalta - Malta]

An excellent course: well done to trainers, excellent delivery & training material.

[Jesmond Silvio - Manager, Process and Performance - Malta Enterprise - Malta]

Excellent course, excellent presentation and dialogue.

[Peter Pace - BPR Analyst - Enemalta Corporation - Malta]

Excellent course. To have what others don't, be prepared to do what others won't.

[Debbie Gatt - Business Re-engineer - Enemalta Corporation - Malta]

An excellent course.

[Stephen Aquilina - ICT Data Analyst - Enemalta Corporation - Malta]

An excellent course, which presents the obvious day-to-day problems which sometimes we do not think or try to solve.

[Christopher Borg - Process Manager - De La Rue - Malta]

An excellent course. I would love to express what I have learnt in these two days to my superiors so together, even on a small scale in my section, we can try and implement some of the lean techniques to improve productivity and job satisfaction of all team players. As a start, I will try to implement lean techniques myself.

[Sylvana Scicluna - Project Engineer - Enemalta Corporation - Malta]

An excellent workshop.

[Ivan Muscat - Director - MIB Management Services - Malta]

Straight to the point! Very lean.... I like!!

[Debbie Gatt - BPR Analyst - Enemalta Corporation - Malta]

An excellent course

[Dolores Galea - Performance + HRD Executive - Malta Enterprise - Malta]

An excellent course, very well delivered

[Marianne Copperstone - Senior Executive - Malta Enterprise - Malta]

An excellent course

[Deborah Gaffiero - Financial Controller + HR Manager - Carlo Gavazzi Ltd - Malta]

An excellent course

[Pauline Saliba - HR Manager - Arriva Malta - Malta]

An excellent course - thank you for these 3 days of inspiration

[Igor Zbirka - R&D Project Leader - Carlo Gavazzi Ltd - Malta]

An excellent course

[Roger Galea - R&D Manager - Carlo Gavazzi Ltd - Malta]

An excellent course. Thanks for explaining very well all topics and making the sessions interesting

[Joseph Thomas Ellul - Project Leader - Carlo Gavazzi Ltd - Malta]

Excellent course in stimulating the potential of the brain and brilliant opportunities waiting just behind the corner!

[Adrian Borg - Head of Pilot Plant - Medichem Manufacturing - Malta]

An excellent course. Thank you for the wonderful experience and for the knowledge you shared

[Stephen Aquilina - ICT Data Analyst - Enemalta Corporation - Malta]

An excellent course. As usual, very effective delivery and great workshop ideas.

[Peter Pace - BPR Analyst - Enemalta Corporation - Malta]

| QUICK LINKS | ||||

| Announcement | Programme | Expression of Interest - Enquiries | About Your Facilitators | Testimonials |