|

navigation

consulting

services

training

services

specials

reading

material

resources

|

The starting point is understanding processes and distinguishing between processes.

Under the Process Engineering angle of view an enterprise operates "per processes".

But there are processes and processes:

- First of all, in every enterprise, there is a Central Process, the money generation process. This is normally articulated in various core processes (see below), all addressed to satisfy the 1st supporting group (clients, consumers....)

- In every enterprise there are CRITICAL PROCESSES, also called core processes (processes that "touch" the customers).

Many of them support/belong to the Central Process.

Obviously, they deserve the utmost attention. Examples:

Sales process

Marketing process

Orders receiving process

Customer relations process

Product Despatch process

New Products/Services Development process

Billing process, etc.

- In every enterprise there are also CRITICAL SUB-PROCESSES and SUPPORT PROCESSES (invisible to customers, but essential for enterprise's functioning). Examples:

Plant/Technology Maintenance process

Personnel Recruitment process

Administration process

Accounting process, etc.

- Finally, in every enterprise, there are Processes addressed to the satisfaction of other supporting Groups, also to be considered as clients. For instance:

Owner/s - Shareholders

Employees

Suppliers

Institutional and Regulating Bodies (government, bureau of standards, normalisation bodies......)

Process Engineering tactics are to consider each process and sub-process as (internal or external) client-driven. As such, strategically significant with regard to the success or failure of the enterprise.

Next step is to set adequate criteria for evaluation and measure of process/es' efficiency and effectiveness (overall performance).

The target is: FLOW PROCESS (Lean Process) or process with no waste.

The methods: elimination of un-necessary activities (all non-value-adding activities) - unification and integration of the significant and essential remaining activities (value-adding activities), in logical, rational sequence, with no gap, no white space (and no black hole) in between, in a linear flowing mode.

The techniques: these vary from industry to industry, as well as from the type (core/support) of the process, and depend also on the degree of mechanisation/automation present in each process.

The Flow Process technique is typical of the Service Industry. For productive Manufacturing Processes, for instance, the discipline to be applied is Flow Production, the heart of Lean Manufacturing (more »).

In construction work, similarly, the Lean Project principle is the applicable technique (more »).

Generally speaking, in all industrial and commercial sectors, the governing discipline and philosophy is Lean Thinking (more »).

Generally speaking, there are some essential requirements to obtain a flow process:

- There must be a Process Owner. This is the person, one and one only, in charge of the process, fully responsible for its output and for the overall process performance.

- Process Operators (be they workers, machine operators, or service personnel) are normally multi-skilled and multi-function, i.e. capable of executing a number of different activities, ideally all the activities of the process.

Activities normally include all quality assurance/control activities necessary to guarantee the conformity of the output.

When one person is sufficient to perform the entire process, we call the Process Operator case worker (typical of the Service Industry). That person is also the process owner.

When the complexity/entity of the process requires more than one person to execute the various process activities, we have a Process Team, also called case team (Service Industry). The Team Leader is the process owner.

- The process must be fully identified and defined: in the input as well as in the output side. Input resources (in terms of man-hours, machine hours, materials, processing specifications, etc.) are clearly identified. Output features (all quality, time and service parameters related to the object output) are comprehensively specified.

- A plan and a budget are attached to the process. This allow "in-process measure of the process efficiency", competence of the process owner.

Measurements and feed-backs are in real-time. The score must be immediately known.

Gaps and deviation from the optimum must be rectified through corrective actions, care of the process owner.

- Also process effectiveness must be known immediately or in short time. Feed-backs on Client's satisfaction should be timely and comprehensive.

Any discrepancy from the optimum should lead to corrective actions, care of the process owner.

- Processes are not rigid. To the contrary, they should be flexible, to cater for personalisation or exceptions if requested by clients.

As such, Process Operators must be flexible, reactive, prepared to learn, open to change.

- Process Operators are not only trained to take corrective actions in respect of non-adequately performing processes, but also to improve, on an ongoing basis, the overall process' performance.

- Plant, machines and, generally, technology utilised in the process should be dedicated, simple, compact, human, easily maintainable and easily settable.

The accent is on quality rather than efficiency. Efficiency (capacity) should be enough to cope with the required output.

More specific requirements may be applicable to certain processes.

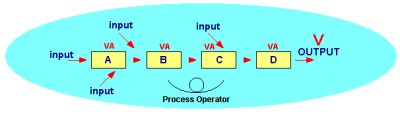

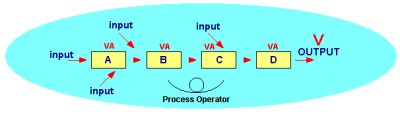

In its simplest case (one Process Operator) a Flow Process may be schematised as follows:

One multi-skilled, multi-function Process Operator carries out a number of sequential value-adding activities until the output is produced.

There is no gap or time-delay between activities: work flows at a well defined pitch (work has a rhythm...).

The process is simple: complexity is a feature of fragmented, old-world processes. New-world Flow Processes are simple and human.

The process is well efficient, and efficiency is measured in real time and known to the Operator.

The process is effective and produces a valuable output. Effectiveness is also measured timely and made known to the Operator.

Discrepancies between theoretical and real efficiency and effectiveness are rectified by means of corrective actions initiated/performed by the Operator.

Process waste has been reduced to a bare minimum. Any residual waste is discovered and eliminated by means of improvement actions, initiated by the Process Operator.

As such, the Process Operator is in full charge of the process: he/she has full responsibility for its overall performance (the score is known....) and is empowered to manage it and improve it. This leads to high job-satisfaction.

The process is built around client's needs and expectations, and is flexible enough to cope with personalisation and/or exceptions.

A Flow Process requires minimal supervision or none at all. Management actions are shifted from supervision/control to coaching (training and support).

The above is a flash representation of the new-world principles.

From: internal attention to: attention to client

From: attention to task to: attention to process

From: simple tasks to: simple processes

From: function units to: process units

Adam Smith's chapter is closed.

The world-class enterprise is structured per and around processes.

The structure is horizontal, not vertical.

The enterprise is seen as a processing system, related to and driven by the market. This is a reactive, responding organisation.

The pyramid is still present: but flatter, smaller, in the background.

The focus is on processes as flow of work.

Supplier/Client relationships, internal and external, are highlighted and stressed.

The top target is process performance

Processes are simple, human, easily manageable.

White space is minimal or nil.

The motto is: small and simple is beautiful (heritage of the Italian Model).

This is the Second Industrial Revolution.

|