|

CELL MANUFACTURING

In labour-intensive and also in labour/machine-intensive situations, Cell Manufacturing is an extremely smart way of implementing Flow Production and progressing towards Lean Manufacturing status (more »).

The principle is simple: a number of manufacturing activities and associated processing stations are positioned in processing sequence in a cell, conveniently shaped.

The cell operator or operators move along the cell and perform the processing activities in a value-adding sequence - flow-process style - minimising/eliminating all waste in between.

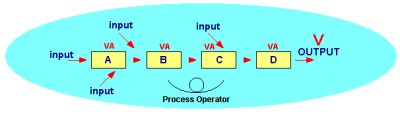

In its simplest shape the cell is just a straight line:

Many other shapes are used in manufacturing, including:

Machines, including heavy pieces of equipment, may be conveniently located in processing cells. Machines, including heavy pieces of equipment, may be conveniently located in processing cells.

For enhanced flexibility, in a Lean Factory all pieces of equipment should be fitted with wheels: this would allow their easy removal from one cell to another, as the need arises.

In fact, in a Lean factory, everything is on wheels: workbenches, tool cabinets, product containers, etc.

Moreover, if all "services" (like electrical power, compressed air, water, steam, etc.) are provided "from the top", and are rapidly connectable to machines (by means of pneumatic and electric quick couplings....), the factory floor becomes finally "free" and "owned" again.

This facilitates fast set-up of manufacturing cells.

In many instances, designing a manufacturing cell is rather complex. In many instances, designing a manufacturing cell is rather complex.

Critical machines need to be used in different cells, or, more common, cells must be designed to cater for production of different products with the same machines.

Accurate feasibility studies must be carried out before switching over from batch production to flow and cell production. The study normally includes Process Mapping, Process Razing, Technology Grouping (or Group Technology, as it is generally called).

These kind of studies normally form part of a Value Stream Mapping (more ») exercise, carried out by one or more Teams.

The resulting cells are often called Group Technology Cells (GT Cells) (because machines have been rationally grouped and included in a cell).

Processing style may require several operators simultaneously in a cell or in two adjacent cells. In certain instances, to assure adequate utilisation of machine/s capacity, operators must "chase" each other in a cell.

Results achievable through flow-cell manufacturing compared to traditional batch processing may be astonishing: productivity (output per person) increases (typical) of about 35% - in some instances, it may increase of up to 100% (double), maintaining the same production capacity (or at least the required takt output) - quality may easily jump to the zero defects target - throughput time reduces to the mere sum of value-adding times.

Most probably, however, the best result is in the human factor. Most probably, however, the best result is in the human factor.

Cell workers, multi-skill and multi-function operators, are finally given a possibility of regaining their professional dignity, stolen in several decades of mass/batch production.

Finally they return to be craftsmen in their shop, proud of the results they achieve and of the wealth they generate: for themselves, for the enterprise, for the customers... proud to make a "product" and not a "fragment" of it.... ...deeply involved and committed to improve systematically an already excellent set-up....

Adam Smith era is over

CONTINUOUS FLOW MANUFACTURING

The extrapolation of the Cell principle leads to the more general principle of Continuous Flow Manufacturing:

- Processing Machines, Lines, and generally Processing Stations are closely linked together in the flow sequence, the output of the upstream Station being fed immediately into the downstream Station - whenever feasible, in a one-piece-flow style.

- Redundant Processing Stations in between are eliminated (f.i. QC stations)

- Lines are integrated together

The ideal situation (utopia, but can be achieved) is when the entire "stream" flows at a speed in line with the TAKT TIME for that product or range of products.

Results of this nature are generally obtained through a Value Stream Mapping (more ») exercise, but not necessarily.

In certain instances it is possible to take a shortcut: starting from the most downstream stations, the Continuous Flow principle is gradually extended upstream.

Lean Manufacturing allied disciplines:

read more » about Achieving Quick Change-Over

read more » about Total Productive Maintenance

read more » about the 6-Sigma Methodology

read more » about the 0-defects - Poka-Yoke approach

read more » about the Value Stream Mapping discipline

|